Continued from Part 1 on THE IMPORTANCE OF LOAD SECURING. Click here to read Part 1.

Tie-down Lashing

Tie-down lashing is the most common type of lashing for the transport of goods over the road. If the cargo is wide (if not wider than the truck tray), securing the load is only possible by vertical or slightly inclined tie-down lashing.

In the case of tie-down lashing, care must be taken to consider factors such as:

Note: Tie-down lashing only works if there is enough friction between the loading area and the load. For example, a steel load on a steel loading area does not offer enough friction which is why wooden supports or anti-slip mats should be used to increase friction.

Diagonal Lashing

For diagonal lashing, two angle plans (horizontal and vertical) should be considered and two angles defined. Diagonal lashing should be prioritised over tie-down lashing. This is because with diagonal lashing, the lashing equipment is not subject to pre-tensioning forces. The lashing equipment is only subjected to higher loads in the event of sudden braking, jerky start, or close cornering.

Are Lifting Points suitable for Lashing?

Lifting points are often installed for lashing purposes. However, lifting points are used primarily for lifting and therefore not marked with the permissible tensile force LC (Lashing Capacity - daN) but with their WLL (tonne). It is important to know that lashing points and lifting points are subject to different design factors. This is why you will find it easier to meet practical requirements with high-strength, tested, and field-proven RUD lashing points.

Weldable RUD lashing points are forged and available in blocks that can be easily welded. RUD lashing points with LC specification in daN can also be retrofitted to the vehicle carrier by certified welders. In addition to these weldable lashing points, RUD also offers an extensive range of boltable lashing points which can be used for load securing.

Tips for Skip Loaders - Optimum Load Securing with Angled Lashing

Load securing is always about the safety of people and the load. Also, having your load secure ensures that you do not run the risk of fines by the transport authorities. With RUD lashing products you be assured of safe transport of your cargo all the time.

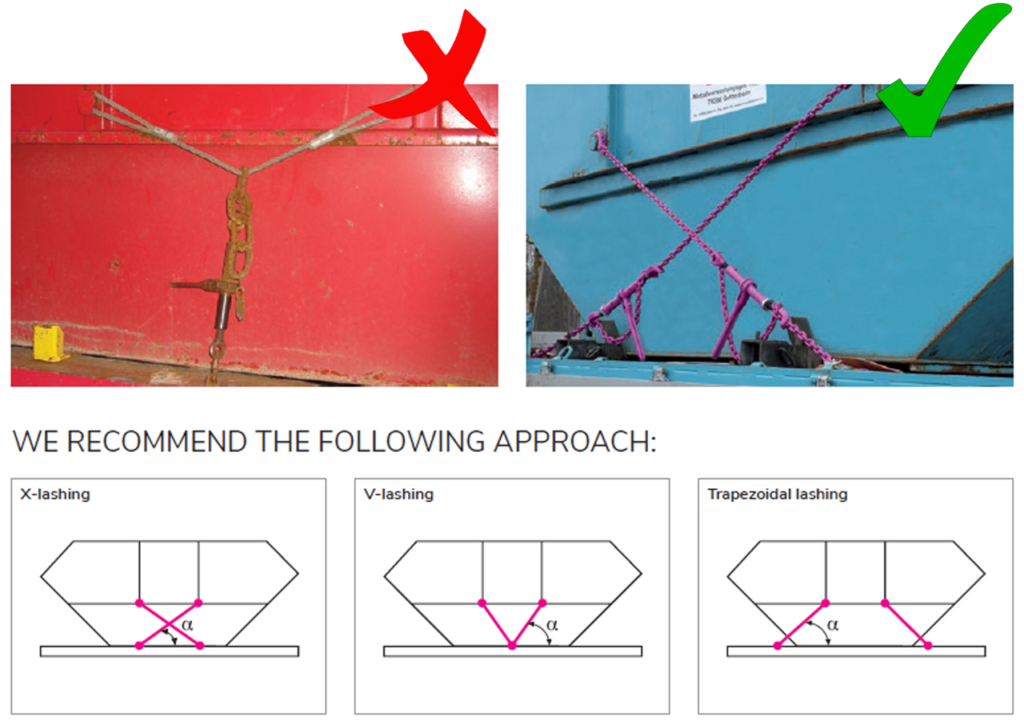

As shown in the pictures, tie-down lashing of trough containers is advisable in V, X, or trapezoidal angles with a fixed connection at the lashing point and the suspension pin. A Y lashing should be avoided because the load will not be adequately secured with this type of lashing.

Finally

If you are transporting heavy machines or cargo, it is important to plan load securing during the design phase components. This means, installing lashing points on both the load and the loading area.

Some of the points to note:

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

We are happy to deal with RUD because of their product quality, customer service and competitive pricing. They are very efficient when submitting quotes with a short lead time and are always available when we need them.

Onsite support is excellent and always professional.

RUD Chains has a great product with an exceptional back-up and field service. We have previously bought from Chinese manufacturers and European companies, but we will stay with RUD due to the quality of the product and availability of service personnel.

Patterson Crane Hire loves a challenge and RUD lifting gear helps us solve these challenges. The weight saving gains when we use their Grade 120 ICE range really makes a difference and minimises our risk when we are managing difficult, heavy lifts.

Simply put, this is why we choose to work with quality suppliers like RUD.

At Holcim (Werribee) we rely on RUD Tyre Protection Chains. Their strong expertise and professionalism is on display when they fit and maintain our chains on site. The team works hard to keep us safe, enable our machines to stay in operation and minimise our costs.

Air & Allied Sales (Pacific) has partnered with RUD Chains for the past 25 years to deliver outstanding engineered solutions. The professional and continued relationship with Ian and his team allows us to continue to support our customers above and beyond their needs.

Our recent requirements have pushed the limits of a standard supplier’s capabilities, but RUD Chains have never...

As Managing Director of ACRAN, we are always excited to provide innovative and quality technical solutions to the market for industrial ventilation, filtration and noise control solutions.

Recently we completed a project where RUD chain drives provided a controlled drive solution for an Engineered lift and fulfilled the requirements. ACRAN is grateful for the technical and on-site...

At Gemilang, we’re confident that our high-quality Endurequip-made Portalifts and vehicle stands will continue to serve us well as we build more buses for the Australian market. These provide us unparalleled underbody access, thereby giving our clients the reassurance that every single bus component, from top to bottom, is designed, manufactured, secured and inspected thoroughly by our...

The team at Jilalan appreciate the quality service you provided in the design, fabrication and commissioning of our platforms for our Wagon remediation project.

RUD's attention to detail and great communications skills ensured that our project was completed to the highest standard and exceeded our expectations. From the start of the procurement process you committed to ensuring time...

Grima Recycling have been working the team at RUD in realising our plant expansion project. The modular RUD chain conveyor has proved to be reliable and effective for the transfer of our recycled products from the loader hopper and up the inclined slop as part of our new process line. The regular contact and support provided by RUD compliments the RUD system quality.

ENCO Precast have been involved with RUD for over 10 years now, predominantly for the supply of the Philipp Group Lifting Hoops for Prestressed Precast Concrete elements for bridges. The engineering support led by RUD's Engineering Manager Matt Pauli is always outstanding and has kept us loyal to RUD.

RUD’s service and product support have been excellent. We are happy to recommend RUD to anyone who has problems with their tyre life.