This is a 2 part article.

The age-old proverb, "A chain is only as strong as its weakest link," first used in Thomas Reid’s “Essays on the Intellectual Powers of Man” in 1786, perfectly encapsulates the critical role of lifting chains in material handling. This article delves into the world of lifting chains, exploring their types, grades, uses, and essential safety considerations.

What are Lifting Chains?

Lifting chains are crucial connectors between a load and a lifting hook. They are typically secured to a designated lifting point on the load, ensuring safe and secure lifting. Lifting chains form part of chain suspensions, which, along with the chains, include a master link, end components like hooks, connecting or shortening components and balancers if required.

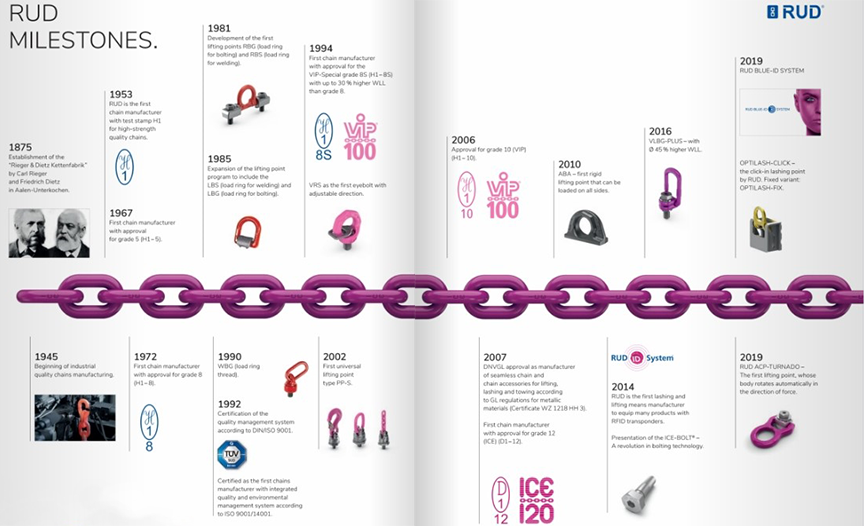

Evolution of Lifting Chains:

Modern lifting chains have significantly improved compared to their predecessors. While past chains suffered from low material strength and cumbersome weight, today's chains offer high strength, durability, and cost-effectiveness, making them the preferred choice for lifting and lashing applications. They also weigh considerably less for the same WLL (Working Load Limit), which is beneficial when lifting heavy loads.

Types of Lifting Equipment:

While wire rope and synthetic slings offer alternative lifting options, they have limitations, particularly in terms of adjustability, susceptibility to sharp edges, and performance under extreme temperatures.

Lifting chains stand out with their:

Choosing the Right Chain Grade:

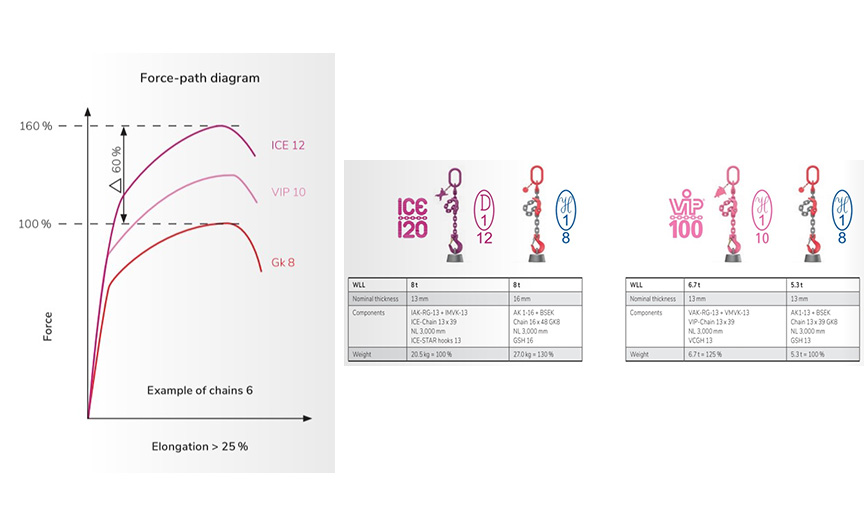

Several chain grades (Grade 80, 100, 120) exist, each with its own WLL (Working Load Limit). Selecting the appropriate grade is crucial for safety and efficiency.

Grade 80: This has been in existence since 1970. It is very popular in some parts of the world because it offers affordability. However, it has a lower breaking force and weight limitation.

Tip: RUD was the first chain manufacturer, approved for Grade 80 in 1972

Grade 100: It has been in existence for the last 30 years and is popularly used by many operators. It is a step up over Grade 80 and provides a balance between cost and performance.

Tip: RUD launched Grade 100 as VIP (Verwechslungsfrei in Pink) in 2006, and it is still a popular product used in many lifting applications. Click here for more details on the RUD VIP Grade 100.

Grade 120: Grade 120 is the latest and strongest grade, offering lighter weight and higher breaking force than Grade 80. Exclusive to a few manufacturers (including RUD).

Tip: Grade 120 offers a 30% reduction in weight than Grade 80 because it uses less material. It also possesses a 60% higher breaking force than a Grade 80 chain, and it is extremely robust, tough, and resilient to sharp and rough edges.

What this means is that an ICE Grade 120 Lifting or Lashing Chain - no matter the nominal thickness - can replace a Grade 80 chain of a next-higher nominal thickness.

Click here for more details on RUD ICE 120 Chains.

To be continued ...

Article copyright to RUD Australia. This information is accurate at the time of publication, and RUD Australia takes no responsibility for any errors, inadvertent or otherwise. Some pictures are for illustration only.

We are happy to deal with RUD because of their product quality, customer service and competitive pricing. They are very efficient when submitting quotes with a short lead time and are always available when we need them.

Onsite support is excellent and always professional.

RUD Chains has a great product with an exceptional back-up and field service. We have previously bought from Chinese manufacturers and European companies, but we will stay with RUD due to the quality of the product and availability of service personnel.

Patterson Crane Hire loves a challenge and RUD lifting gear helps us solve these challenges. The weight saving gains when we use their Grade 120 ICE range really makes a difference and minimises our risk when we are managing difficult, heavy lifts.

Simply put, this is why we choose to work with quality suppliers like RUD.

At Holcim (Werribee) we rely on RUD Tyre Protection Chains. Their strong expertise and professionalism is on display when they fit and maintain our chains on site. The team works hard to keep us safe, enable our machines to stay in operation and minimise our costs.

Air & Allied Sales (Pacific) has partnered with RUD Chains for the past 25 years to deliver outstanding engineered solutions. The professional and continued relationship with Ian and his team allows us to continue to support our customers above and beyond their needs.

Our recent requirements have pushed the limits of a standard supplier’s capabilities, but RUD Chains have never...

As Managing Director of ACRAN, we are always excited to provide innovative and quality technical solutions to the market for industrial ventilation, filtration and noise control solutions.

Recently we completed a project where RUD chain drives provided a controlled drive solution for an Engineered lift and fulfilled the requirements. ACRAN is grateful for the technical and on-site...

At Gemilang, we’re confident that our high-quality Endurequip-made Portalifts and vehicle stands will continue to serve us well as we build more buses for the Australian market. These provide us unparalleled underbody access, thereby giving our clients the reassurance that every single bus component, from top to bottom, is designed, manufactured, secured and inspected thoroughly by our...

The team at Jilalan appreciate the quality service you provided in the design, fabrication and commissioning of our platforms for our Wagon remediation project.

RUD's attention to detail and great communications skills ensured that our project was completed to the highest standard and exceeded our expectations. From the start of the procurement process you committed to ensuring time...

Grima Recycling have been working the team at RUD in realising our plant expansion project. The modular RUD chain conveyor has proved to be reliable and effective for the transfer of our recycled products from the loader hopper and up the inclined slop as part of our new process line. The regular contact and support provided by RUD compliments the RUD system quality.

ENCO Precast have been involved with RUD for over 10 years now, predominantly for the supply of the Philipp Group Lifting Hoops for Prestressed Precast Concrete elements for bridges. The engineering support led by RUD's Engineering Manager Matt Pauli is always outstanding and has kept us loyal to RUD.

RUD’s service and product support have been excellent. We are happy to recommend RUD to anyone who has problems with their tyre life.