Our Quarry Chains

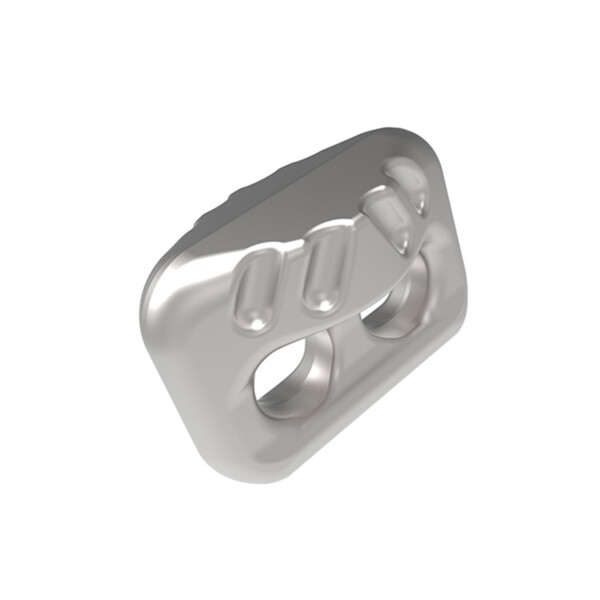

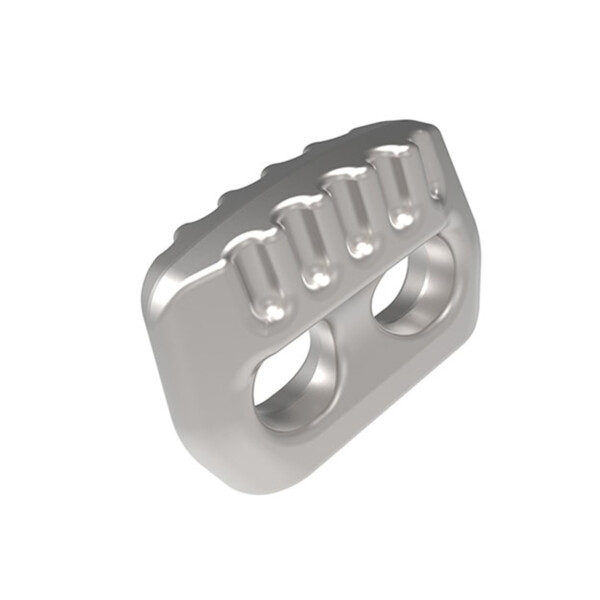

Mucky, slippery, and sharp surfaces are a huge obstacle for tyres. Quartz silica, dolomite, basalt, and granite are a few of the causes of excessive tyre wear. Flint, slate, and shale-like rock or demolition of debris can cause punctures and sidewall cuts. The density of the required chain mesh required will depend on the exact specifications of the work site. In every case, the mesh will be self-cleaning, and the links are specially hardened to resist wear at the points in which they interact with the connecting rings.

One moment, your loader could be crowding into the rock fall; the next, it is slumped and immobile. You are now looking for a temporary fix or replacement and left with a costly standby for your operation that a tyre protection chain would have prevented.

A Tyre Protection Chain is ideal for creating a barrier between the tyres and the ground surface. TPC’s provide maximum protection to sidewalls and tread areas, virtually eliminating tyre failures from rock cuts and staking. This guarantees maximum production from the loader and peace of mind with unplanned tyre maintenance expenses.