RUD’s apron conveyors are suitable for a wide range of applications, such as high-temperature materials, waste, aggregate, dry ash handling, mineral processing, and kiln applications.

RUD apron feeders increase the efficiency of bulk material handling in high-temperature and high-abrasive applications. They are extremely versatile and can convey bulk materials without causing spillage or degradation.

The advantages of a RUD Apron Feeder Conveyor are:

Project:

RUD Australia was tasked to design, build and install an apron feeder conveyor for an automotive recycling operation. The scope of the project was to offer a complete solution to solve issues around moving shredded auto parts.

Challenges:

The outdated handling process had individual aprons with rollers installed that required constant maintenance. The goal was to increase production and reliability while minimising maintenance and unplanned shutdowns.

Available data at the engagement stage:

The RUD Solution:

RUD designed, manufactured and commissioned a workable solution as part of the improvement project. The RUD-engineered round steel chains proved to be a successful improvement over the plate and bushing pin-type chains.

The Result:

Comments:

Technical Details:

| Specifications | Dimensions |

| Horizontal Conveying Length | 8.2 Metres. |

| Hopper Capacity | 24 m3. |

| Inclined Conveying Length | 7 Metres. |

| Horizontal Conveying Length - Top | 0.65 Metres. |

| Linear Speed | 0.1 m/s typical speed 0.2 m/s maximum. |

| Conveyed Material | 50mm average height of material, 900Kg/m³ average density, process 50T p/hr. |

| Chain Capacity | 566kN (break load). |

| Apron Pans | 89 pieces at 480 centres, each weighing 120kg. Minimum 1550mm wide. |

If you want to know how the team at RUD can help you, please call us on 07 3809 1300 or fill out an enquiry form here.

The reliability and safety of our products are central to our business. Our quality commitment is reflected in our integrated QM / UM-System, which ensures all RUD employees comply with the high quality and environmental standards set by us.

1953 marked a turning point in the history of the hoist industry when RUD became the first company to receive the H stamp for high-strength chains. The H stamp, which symbolises quality and safety, has revolutionised the world of lifting and lashing. RUD is the first manufacturer of new quality grades and carries the H1-stamp for Grade 60, Grade 80 and Grade 100. Seven decades later, RUD is still at the forefront of innovation.

Watch the new video, which looks at the stamp's origins and its role in quality and safety.

Welcome aboard Australia’s leading material lifting and handling technology company.

Click the button to read about us, our products, news, blog posts and everything happening at RUD in Australia and around the world.

A gangway is a narrow walkway or platform that provides safe access to a ship, truck, or train. Ship gangways are used for the passage of both passengers/crew and cargo. They must move in all directions and be height-adjustable for use with different ships. The gangways must also be robust, secure and safe under challenging conditions.

RUD’s TECDOS Drive system offers an ideal solution for a gangway, using calibrated steel chains fitting into complimenting sprockets. TECDOS drive systems are an ideal replacement for pinion gear and wire rope drives because they function reliably even under the most challenging conditions.

For gangways, RUD TECDOS drive systems can include:

TECDOS PI-GAMMA DRIVE

PI-GAMMA drive system with a fixed 180-degree angle (PI) or a flexible angle of 90-180 degrees (GAMMA) is suited for horizontal and vertical applications. The PI-GAMMA pocket wheel block can pull the load along the round steel chain or move it to a different location.

The advantages of PI-GAMMA DRIVE:

TECDOS PREMIUM ROUND LINK CHAIN

The core component of each TECDOS drive system is a highly wear-resistant, calibrated round link chain that can be used in challenging conditions or with abrasive materials. TECDOS chains have high-grade strength to ensure maximum operating safety. The Premium Round Link Chain is case-hardened.

TECDOS END CHAIN FIXING

The chain end fixing to connect chains to supporting structures transfers 100% of the TECDOS chain operating forces. Because of its adjustable axis, it also ensures maximum flexibility during use.

TECDOS LIFT LIMITER

The lift limiter prevents the chain from “passing through” by limiting the unloaded sides of the chain, working as a route limiter.

The Project:

RUD Australia was approached to build a passenger gangway for a cruise ship terminal in Western Australia. The client could not implement the standard method of using a hydraulic cylinder, as it was too expensive and not cost-efficient for the required lift height.

The Solution:

After understanding the scope of the project and the solution that best met the client's requirements, RUD developed a dual-strand loop drive component package for this project.

The Result:

RUD implemented a TECDOS 65 component package. Gear motors independently drove the Pi Drives.

The Project Inclusions:

TECDOS systems are ideal for applications where materials or equipment need to be swivelled, lifted, moved, or rotated safely and reliably. RUD quality is a result of years of research and development, creating bespoke drive solutions that are used by leading companies in maritime, engineering, automotive, and wind power and by military forces around the world.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors, inadvertent or otherwise.

For more details on how RUD can help with your crane requirements, please call us on 07 3809 1300 or fill out an enquiry form here.

Sources:

Welcome aboard Australia’s leading material lifting and handling technology company.

Click the button to read about us, our products, news, blog posts and everything happening at RUD in Australia and around the world.

Drive Solutions for Stage and Events

Entertainment is big business. All musical and sporting events require smooth behind-the-scenes operations to create magic for the audiences. Many stadiums, opera houses and theatre buildings are constructed or renovated to accommodate a wide variety of events, from sports to live theatre, music concerts and dance performances. Hence, the stage needs to adapt quickly to new areas or shapes to accommodate the demanding requirements of such events. And the only way is by using systems such as mechanical chains that lift, lower, push, and pull equipment into a variety of configurations.

Every stage is different, which means that each component of the stage not only has to be durable and efficient but must also integrate into the whole equipment. Theatre and stage construction present technical challenges because of high loads on crossbeams, stage lighting, stage sets or entire stage platforms, which must move safely and reliably. In addition, technical equipment must operate quietly and out of sight, so as not to interfere with the performance.

A long history

RUD has been a world leader in lifting and drive technology with a history of manufacturing excellence for over 140 plus years.

The magic of a show is priceless. Many opera houses, theatres and stadiums across the world use RUD hoist chains and drive solutions that reliably raise and lower stage equipment such as crossbeams, platforms and curtains including setting up and dismantling shows. RUD chains and drive solutions also enable the smooth realignment of permanently installed lightning. Every event is unique and using RUD chains and drive technology guarantees a safe and easy process including customisation for each performance as required.

TECDOS from RUD is a drive system that combines high-quality and accurately calibrated steel chains which fit into complementing sprockets. TECDOS modules are suitable for high loads and reliable under the most challenging conditions. Every TECDOS round steel chain is stamped and issued with a standard 3.1 inspection certificate to ensure its traceability right back to the chain furnace.

Solutions for the entertainment industry:

All RUD products are finished in Galvanised Black Phosphate to blend with the stage equipment.

CASE-HARDENED ROUND STEEL CHAINS

Case-hardened RUD chains of RTS, RTD and RTB are the safe option for every electric hoist which require reliability and safety.

The benefits of RUD Case-Hardened round chains are:

D-PROFILE CHAIN

RUD D-profile chain, the round steel chain 2.0, is the leading technologically advanced round steel chain. Because of its large cross-sectional area, it has a higher maximum load, is case-hardened and designed for higher wear demands.

The benefits of RUD D-Profile chains are:

TECDOS DRIVE TECHNOLOGY

RUD TECDOS products can manage the lifting and moving of all stage elements, safely and reliably.

Some of the TECDOS products used for stage operations are:

TECDOS ROUND LINK CHAIN: The core component of every TECDOS system application is a highly wear-resistant RUD round link chain for maximum service life.

TECDOS PI-GAMMA: The 2 in 1 Pi-Gamma is suited for horizontal and vertical applications with a fixed 180 degree application, or a flexible 90 to 180 degree application. The drive system ensures greater efficiency through flexibility.

TECDOS OMEGA DRIVE: TECDOS Omega Drive with a wrap angle of 180 degrees is recommended for continuous linear (linear drive) or rotary movements.

TECDOS Pocket Wheel: TECDOS pocket wheels are optimally designed to fit round link chains for smooth running and long service life.

TECDOS Chain Connector: The highly wear-resistant chain connector forms a reliable connection system even under challenging conditions. Endless chain loops are possible by means of a simple hammer assembly.

TECDOS Chain End Fixing: The chain end fixing for connecting chains to supporting structures transfers 100% of the TECDOS chain operating forces. Due to its adjustable axis, it ensures maximum flexibility during use.

TECDOS PowerPoint Lifting Point: The PowerPoint lifting point for connection to chains, hooks, and eyes, can easily be rotated 360° and swivelled 230°. The double ball bearing ensures easy tilting, turning and rotating for drive technology.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Sources:

RUD is a leading manufacturer of conveyor and drive technology globally. We offer high-quality and innovative conveying solutions which are highly regarded for quality performance and low maintenance in both open-cut and underground mining applications.

In any mine site, the reliability and efficiency of equipment are critical in avoiding unscheduled downtime due to breakdowns. In Australia, RUD has partnered with global materials handling giant, Gambarotta Group and this partnership enables us to offer complete solutions. All RUD conveyor and drive systems use reliable RUD round steel chains, forged link chains, screw drives, or belt drive systems.

The RUD solutions for the mining industry include:

Apron Feeder Conveyors

RUD apron feeder conveyors have a reduced-height design so they are compact and highly suitable for horizontal and bunker loading requirements. These conveyors are wear-resistant, made of quenched and tempered components, capable of handling high loads and engineered to last. RUD’s heavy-duty conveyor applications with premium components offer long life and durability on mine sites.

Trough Chain Conveyors

RUD trough/drag chain conveyors are specifically designed to safely transport powdery, grainy, flaky, or dusty material. They are heat-resistant, hardwearing, and provide the option to use multiple inlets and outlets. RUD drag conveyors can be designed as a sealed unit ensuring emissions are contained within the conveying process.

Spillage Drag Conveyors

RUD spillage chain conveyor systems are suitable for low-profile and reduced-access applications.

The heavy-duty hardened-steel chain systems used in RUD spillage chain conveyors make them a low-maintenance, highly efficient, reliable, and robust conveying solution. Workplace safety is also enhanced as their design eliminates the need to access and clean up under the conveyors.

Screw Conveyors

RUD screw conveyors are low maintenance and are available as single, double, or triple conveyor units to transport material in horizontal, inclined, or vertical applications.

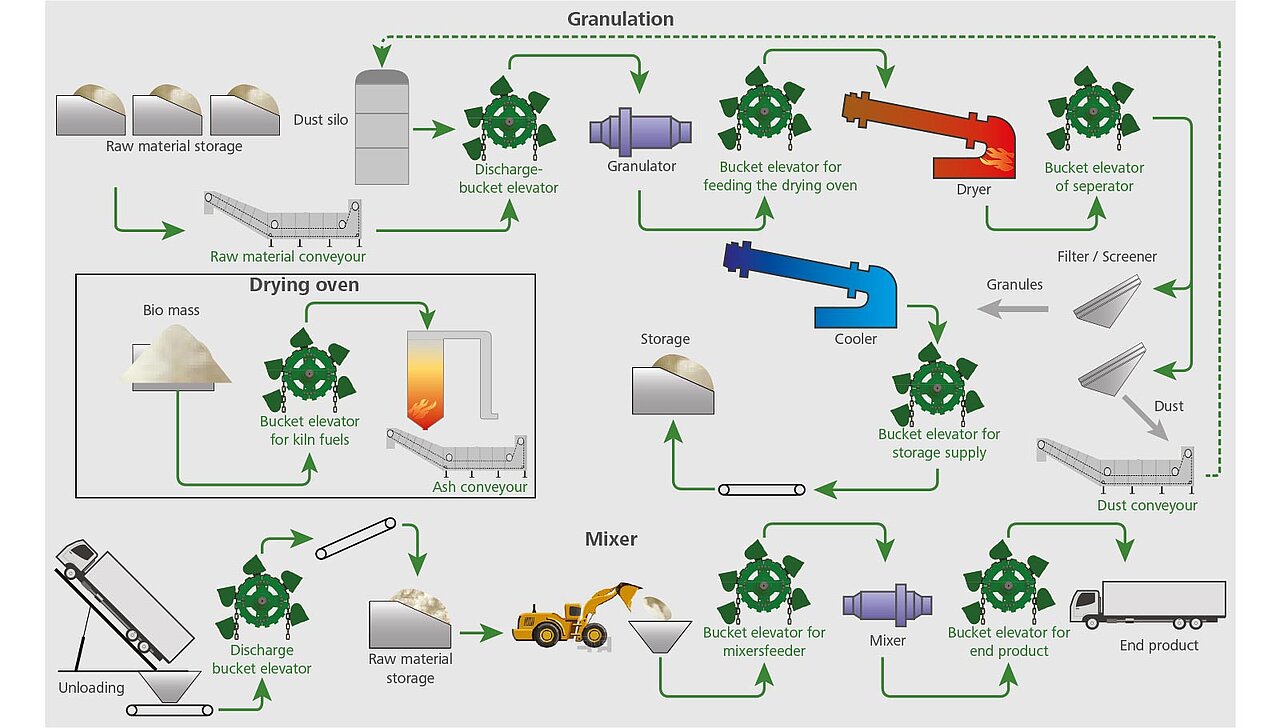

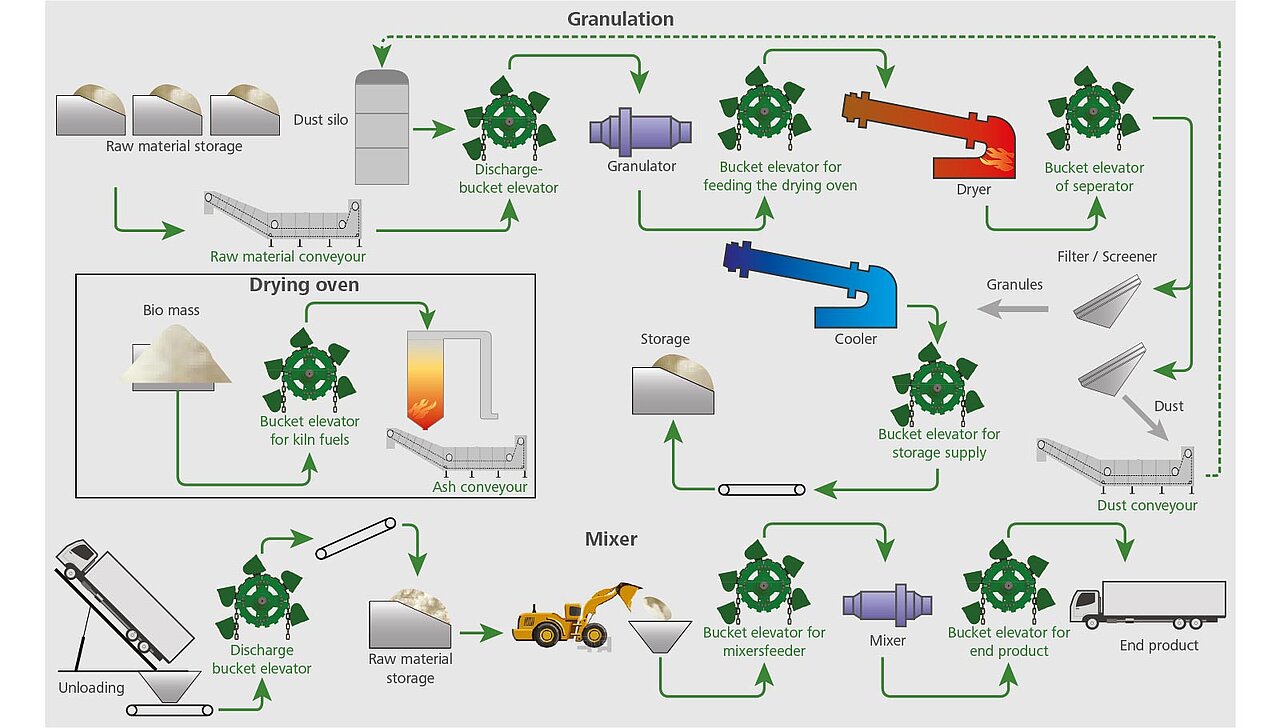

Chain Bucket Elevators

RUD’s range of chain bucket elevator systems is suitable for bulk material handling. Our international expertise in quality elevators has offered solutions to reduce maintenance and operating costs. Our commitment to customers and availability of quality components helps with longer production run times.

RUD’s bucket elevator mounting attachments include:

Belt Bucket Elevators

The reinforced steel or textile inlays found in RUD belt-type bucket elevators guarantee an easy and efficient transport of product in the processing of minerals. The high-temperature rubber composition and fortified belts of RUD elevators make them extremely durable and suitable for a wide range of applications.

Truck Surface Feeders

RUD chain-driven belt feeder conveyors are one of the most eco-friendly conveyor systems because they offer considerably higher efficiency in the form of faster solids processing time, lower thermal energy loss, and waterless operation. They are engineered to last and are capable of handling even the most hazardous waste applications of the mining industry.

Gambarotta truck surface feeders are specifically designed for efficient discharge operations, with the option to adjust the flow rate of the conveying material if required, optimising the processing time.

RUD Group also offers world-renowned tyre protection chains for the mining industry. RUD is the inventor and the world leader in tyre protection chains, supplying 65% of the world’s tyre protection chain market. RUD’s tyre protection chains help to reduce unplanned downtime of front-line production machines and boost safe working conditions on the mine site.

With a state-of-the-art 6000m2 manufacturing facility in Brisbane and a sales/warehouse in Perth, RUD can also offer bespoke engineered solutions. Our qualified team of CPeng/RPEQ engineers can manage every aspect of a mining project with concept-to-completion solutions. Our quality control systems include compliance with Quality ISO 9001, Environmental ISO 14001, and AS 45001 so you can be assured of the highest quality to meet industry standards.

This article was published in the Australian Mining Review April 2023 issue. Article copyright to RUD and AMR, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

Continued from Part 1 on THE BENEFITS OF RUD BLUCKET ELEVATORS. Click here to read Part 1.

Why should you use RUD bucket elevators?

Increased Efficiency

RUD bucket elevators are designed to increase efficiency in mining, power plants and fertiliser plants. By using RUD Chains, the bucket elevators can convey more materials over a short distance than traditional conveyors. They also allow for quicker loading and unloading of materials compared to other elevators. This helps to save time and money, as well as reduce downtime. The high capacity and efficient performance of these elevators makes them the perfect choice for any industrial application that requires reliable and efficient material movement.

Reduced Maintenance Costs

RUD bucket elevators are designed to reduce maintenance costs and increase efficiency. They offer a range of advantages over traditional conveyor systems, including decreased downtime. RUD chains provide superior strength and durability, ensuring that buckets remain secure and upright throughout the elevator's lifecycle. This reduces the need for frequent repairs and replacements, leading to significant savings in maintenance costs. Additionally, RUD chains are made from low-maintenance components, with no need for regular lubrication or adjustment. This further reduces the overall cost of ownership in mining, power plant and fertiliser plant operations.

Increased Capacity

RUD bucket elevators offer an efficient and reliable way to transport materials over long distances or at high capacities. By using RUD chains, the elevators can lift up to 90kg per chain link, providing a strong and reliable system with high throughput. This makes them the perfect choice for transporting materials in power plants, fertiliser plants, and other industrial applications. With the ability to easily handle large volumes of material, RUD bucket elevators can significantly increase production output, reduce downtime, and improve operational efficiency.

Improved Safety

RUD bucket elevators are designed with safety in mind. RUD Chains have a built-in protection system that prevents unauthorised access to the drive system, providing an additional layer of safety when handling heavy loads. The chain is designed with a breakage detection system that automatically stops the elevator and alerts personnel if there is an unexpected increase in the chain tension or an unexpected decrease in chain speed. This ensures that the chain and any material being moved are always under control. The guard rail system also helps safe operation by personnel, preventing accidental contact with the running chains and come equipped with emergency stop buttons.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

Part 1 of a 2 part post.

Large industries in bulk material handling require safe and efficient methods of conveying materials with minimal risk of spillage. Selecting the right conveyor for the process depends on factors such as type of the bulk material, location of the feeding and discharge point and other special requirements such as mixing, hygiene, toxicity in the process, etc.

Bucket Elevators are an ideal method of conveying bulk materials which require vertical elevation. Bucket elevators can handle a wide variety of bulk materials and can be manufactured with steel which offers resistance against abrasion. They also can be completely enclosed, minimising pollution from toxic materials and dust.

RUD is a pioneer in the conveying industry and RUD bucket elevators are sought after world-wide. Some of the advantages of the RUD bucket conveyor systems are:

RUD chain bucket elevators can handle high temperature, abrasive, sticky or sharp bulk materials, compared to belt elevators.

The various types of RUD bucket elevators are:

Round link chain bucket elevators

These are predominantly used for conveying of powdery, granular, lumpy, and temperature-loaded bulk goods. The highly wear-resistant RUD chains and sprockets ensure reliability with abrasive materials. Depending on the application, chain bucket elevators are available in special designs with a constricted chain of buckets or with a central discharge.

Central chain bucket elevators

These are ideally suited for large capacity conveying of coarse dry bulk goods and offer maximum conveying reliability, even when handling charge fluctuations, high-temperature materials, and materials with large single edge lengths.

Belt type bucket elevators

These bucket elevators use textile or steel reinforced belts to transport materials in a continuous dust-free vertical process. Suitable adaptations can be done to handle coarse-grained or higher temperature materials.

Maximum Capacity, Tough Applications, Proven Design

RUD bucket elevators are designed to handle the toughest of materials, making them the ideal solution for a wide range application across many industries.

Continued into Part 2 of WHY SHOULD YOU USE RUD BUCKET ELEVATORS …

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

Continued from Part 1 on TECDOS. Click here to read Part 1.

TECDOS CHAINS

Highly wear resistant for maximum safety

The core component of each TECDOS drive system is a highly wear-resistant, calibrated round link chain which can be used in adverse conditions or with abrasive materials. TECDOS chains have high grade strength to ensure maximum operating safety.

There are 2 types of chains which can be used for a wide range of requirements and applications:

TECDOS CHAIN CONNECTOR

For a reliable connection

TECDOS chain connectors help to connect chains and create a safe connection system. Connecting is easy because the overall dimensions are the same as the chain links. They can be used in both single and multi-strand conveyors, operating in medium to heavy duty conditions.

The advantages of CHAIN CONNECTOR:

TECDOS POCKET WHEEL

To complement TECDOS chains

TECDOS pocket wheels are designed to work with TECDOS chain and are available for single and multi-strand configurations from TEC 6 to TEC 260 sizes and for loads from 6 up to 260 kN.

The advantages of POCKET WHEEL:

TECDOS LIFT LIMITER

The lift limiter prevents the chain from “passing through” by limiting the unloaded sides of the chain, working as a route limiter.

TECDOS SLINGS

The TECDOS sling and lashing systems are available in various products such as:

TECDOS systems are ideal for applications where materials or equipment need to be swivelled, lifted, moved, or rotated safely and reliably. RUD quality is a result of years in research and development, creating bespoke drive solutions that are used by leading companies in maritime, engineering, automotive, wind power and by military forces around the world.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out a form here.

Sources:

Part 1 of a 2 part post.

RUD has been a manufacturer of lifting chains for more than 140 years which are used in chain hoists across the world. In the course of its innovative journey, RUD developed a drive system by combining high quality and accurately calibrated steel chains to fit into complementing sprockets called TECDOS.

TECDOS modules are suitable for high loads and can be installed anywhere. They are an ideal replacement for pinion gear and wire rope drives. The biggest advantage of the RUD TECDOS systems is their reliability to work under the most difficult conditions. TECDOS is used across offshore and onshore projects, ports, jetties, mining, hydraulic steel engineering, entertainment, steel construction and shipbuilding. It is also used to move roofs insports stadiums, swimming pools, spa pools or event venues.

Watch the sliding roof video below:

TECDOS OMEGA DRIVE

For linear or rotating movements

The TECDOS OMEGA drive with a loop angle of 180 degrees is suitable for both continuous linear and rotational movements. OMEGA drive is used in onshore and offshore projects to move cranes, align, and adjust loaders and to open and close cargo space covers on ships. When rotating, the OMEGA drive can also be used to lift and lower platforms, drive ferries, and extend telescopic booms and skidding systems.

The advantages of OMEGA DRIVE:

TECDOS PI-GAMMA DRIVE

For horizontal and vertical systems

PI-GAMMA drive system with a fixed 180-degree angle (PI) or a flexible angle of 90-180 degrees (GAMMA) is suited for horizontal and vertical applications. The PI-GAMMA pocket wheel block can pull the load along the round steel chain or move it to a different location.

Some of the uses of PI-GAMMA DRIVE are:

The advantages of PI-GAMMA DRIVE:

Continued into Part 2 for more TECDOS products …

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out a form here.

Sources:

RUD Australia, the subsidiary of the German-based RUD Group, has been providing innovative conveying solutions for various industries since 1984.

Large projects, commercial operations and complex industrial environments benefit significantly from conveyor systems. The use of conveyor systems helps mitigate the risk of damage or loss to materials being handled. This enables the efficient mechanised handling and transport of materials. Conveyors are particularly useful in challenging industrial settings where there are sizeable workloads and extreme weather conditions considered adverse or unsafe for human labour.

Among the conveying solutions RUD is known for include spillage drag conveyors, apron conveyors, chain-driven belt feeders, bucket elevator conveyors and floatation tank conveyors.

In particular, RUD has developed optimal solutions designed to address the need for safe and efficient conveyor systems in the transport of fertiliser.

During bulk handling and transport, there are ever-present difficulties that industries need to anticipate. These include dust, contamination, and spills that usually occur at the transfer points of conveyor systems. Moreover, there are other problems to look out for, such as abrasion, belt misalignment and damage.

However, what makes fertiliser handling and transport particularly challenging is the added burden of the fertiliser being sticky and moist – thereby posing additional complications to the handling process.

But with RUD’s engineered fertiliser conveying solutions and systems, dust formation, material spillage and the risk of explosions occurring in critical transfer sections are minimised significantly. Moreover, the chance of any misalignment, abrasion and belt damage happening is effectively eliminated.

RUD’s innovative fertiliser conveying solutions include belt bucket elevators and spillage drag conveyors.

RUD bucket elevators enable the safe, quick, precise and efficient vertical transportation of fertiliser, cement, sand, gravel, potash and salt. Quality componentry reduces downtime and allows for maximum efficiency. Read more about this solution.

The heavy-duty, low-maintenance RUD spillage chain conveyor system is built to ensure efficient fertiliser transport in low-profile, reduced-access applications. Spillage chain conveyor systems can be fully enclosed, thereby enabling the safe, dust-free and watertight transport of bulk fertiliser material. Find out more.

Our chain-driven belt feeder conveyors are designed for optimum productivity through a completely waterless operation, with the assurance of safety even when processing hazardous waste. This system allows you to process solids faster and is suitable for both horizontal and inclined operations. Learn more.

With over 140 years of experience in engineered products and solutions and over 500 industrial patents to date, RUD is uniquely placed as an industry leader, forging partnerships with various clients in the fertiliser industry and delivering conveying solutions manufactured according to stringent quality and safety standards. If you have a specific conveying challenge, get in touch with the RUD team today.

Since 1984, RUD Australia has been at the forefront of providing high quality innovative conveying solutions for various industries and applications. Time and again, RUD has developed safe, state-of-the-art chain driven technology designed for the safe handling of a diverse range of materials, such as cement, gravel, limestone, slag, dry ash, minerals, ores, aggregates, steel, coal, and soil and construction waste.

The experience we’ve accumulated through the years has differentiated RUD as an industry leader in providing tailored materials handling solutions that are engineered and manufactured to the highest standards.

One of RUD cutting-edge design and engineering achievements includes new high-performing and low-maintenance conveying solutions designed for the cement and asphalt industries. These include:

Designed to vertically transport granular, lumpy materials like limestone, cement, gravel, and slag, RUD central chain bucket conveyors are efficient and reliable. Durable and fitted with wear-resistant RUD chains, RUD central chain bucket conveyors are also capable of transporting high-temperature materials.

RUD’s bucket elevator mounting attachments include the:

RUD apron feeder conveyors have a reduced-height design so they are compact and highly suitable for horizontal and bunker loading requirements. Wear-resistant and made of heat-treated components, our apron feeder conveyor systems are capable of handling high loads and are engineered to last.

RUD trough chain conveyors are specifically designed for the safe transport of powdery, grainy, flaky, or dusty material used in the chemicals, cement, construction, and recycling industries. They are heat-resistant, hardwearing, and provide the options to use multiple inlets and outlets.

Our chain-driven belt feeder conveyors are one of our most eco-friendly conveyor systems as they offer considerably higher efficiency in the form of faster solids processing time, lower thermal energy loss, and waterless operation.

RUD belt feeder conveyor systems are engineered to last and are capable of handling even the most hazardous waste applications in the energy, mineral, cement, waste handling, and soil and construction waste industries.

RUD spillage chain conveyor systems are suitable for low-profile, reduced-access applications, particularly for dry ash handling, mineral processing, mineral ore, aggregate, steel, and recycling.

The heavy-duty hardened-steel chain systems used in RUD spillage chain conveyors make them a low-maintenance, highly efficient, and robust conveying solution. Workplace safety is also enhanced as their design eliminates the need to access and clean under the conveyors.

The reinforced steel or textile inlays found in RUD belt-type bucket elevators guarantee the easy and efficient transport of limestone, cement, slag, coal, and mineral processing and recycled materials. Their high-temperature rubber composition and fortified belts make RUD belt bucket elevators extremely durable and suitable for a wide range of applications.

Another component of RUD conveying solutions, TECDOS-driven telescopic chutes are suitable for operations in dusty environments. TECDOS components are highly corrosion-resistant, extremely durable, flexible, and customisable. They can be used when refurbishing existing equipment or with new chutes.

RUD conveying systems and components are designed to address specific client requirements to ultimately provide highly efficient, reliable, durable system solutions.

Our innovative engineering technology and mechanised solutions are safe, compliant, and designed to minimise health and safety risks in various operating environments.

If you have any questions about availability or a specific conveying challenge, get in touch with the RUD team today.