Introduction:

Germany, with 34 million tons of cement production, is Europe's leading cement producer*. When TBA, a renowned concrete supplier needed assistance to lift the roof of a concrete silo used for an infrastructure project, they turned to RUD.

The Challenge:

The project required lifting and placing a roof on top of a silo located near Unterkochen.

The project presented several challenges for the lifting operation:

The Solution:

Due to the heavy lift and the lifting configuration, RUD engineers proposed that a 13mm, 2 x 2-strand ICE 120 chain was ideal for the operation. To maintain the chain's working load limit (WLL) within safe parameters, it was calculated that a minimum length of 6.402 meters was required for low sling angles.

However, there were only 2 x 7-metre 2-strand chains and 2 x 4-metre chains in stock. Instead of postponing the project to another date, we decided to use IH (ICE-H) Connectors to extend the 4-metre chains.

The I-H Connectors are a fast, simple, and cost-effective solution for converting ICE chains into endless configurations. They are compact, easier to manage than conventional chain connectors, and flexible enough to fit the ICE chain.

Once the chains were extended to the necessary length, ICE Star Hooks were attached to the chain ends. Due to their innovative skeletal design, ICE Star Hooks can be used in temperatures from -60°C to 300°C and are up to 25% lighter than Grade 80 hooks of the same WLL.

This solution enabled a safe and secure lift of the silo roof. The roof was lifted to its final height of 35 meters above ground for the final assembly.

Products used in the project:

Conclusion:

This project demonstrates how RUD's innovative lifting solutions, such as the flexible ICE Chains, can solve complex lifting challenges. RUD is the innovator and sets standards for lifting technologies through expertise and flexible solutions to ensure safe and successful operation even in challenging conditions.

* The European Cement Association. Key Facts & Figures: Main World Producers in 2018; The European Cement Association: Brussels, Belgium, 2020

Article copyright to RUD Ketten and RUD Australia. This information is accurate at the time of publication, and RUD Australia takes no responsibility for any errors, inadvertent or otherwise. Some pictures are for illustration only.

Part 2 of the 2-part article. Click here to read Part 1.

Identifying Chain Grades:

Chains are stamped with their grade for easy identification. Grades 80 and 100 use the "(H)" stamp followed by the number (e.g., H8 for Grade 80, H10 for Grade 100). However, Grade 120 employs the "(D)" stamp. It is important to point out here that unlike lifting chains, hoist chains cannot be used for lifting and are stamped with letters to prevent potentially dangerous mix-ups.

Safety Certifications and Testing:

Safety is paramount. Always opt for chains approved by relevant regulatory bodies (e.g., DGUV in Germany). Traceability through batch codes and RFID chips (offered by RUD) is also recommended. Regular inspections and electromagnetic crack tests (every three years) are essential for safety assurance.

Choosing the Right Lifting Chain:

Selecting the right chain hinges on several factors.

RUD will help you with the best chain suspension for lifting based on the following:

Conclusion:

By understanding the types, grades, and applications of lifting chains, you can ensure safe and efficient lifting operations. Remember to prioritise safety by adhering to regulations, conducting proper inspections, and selecting the most suitable chain for your specific needs.

Click here to download our Lifting Points and Lifting Means Catalogues.

Article copyright to RUD Australia. This information is accurate at the time of publication, and RUD Australia takes no responsibility for any errors, inadvertent or otherwise. Some pictures are for illustration only.

This is a 2 part article.

The age-old proverb, "A chain is only as strong as its weakest link," first used in Thomas Reid’s “Essays on the Intellectual Powers of Man” in 1786, perfectly encapsulates the critical role of lifting chains in material handling. This article delves into the world of lifting chains, exploring their types, grades, uses, and essential safety considerations.

What are Lifting Chains?

Lifting chains are crucial connectors between a load and a lifting hook. They are typically secured to a designated lifting point on the load, ensuring safe and secure lifting. Lifting chains form part of chain suspensions, which, along with the chains, include a master link, end components like hooks, connecting or shortening components and balancers if required.

Evolution of Lifting Chains:

Modern lifting chains have significantly improved compared to their predecessors. While past chains suffered from low material strength and cumbersome weight, today's chains offer high strength, durability, and cost-effectiveness, making them the preferred choice for lifting and lashing applications. They also weigh considerably less for the same WLL (Working Load Limit), which is beneficial when lifting heavy loads.

Types of Lifting Equipment:

While wire rope and synthetic slings offer alternative lifting options, they have limitations, particularly in terms of adjustability, susceptibility to sharp edges, and performance under extreme temperatures.

Lifting chains stand out with their:

Choosing the Right Chain Grade:

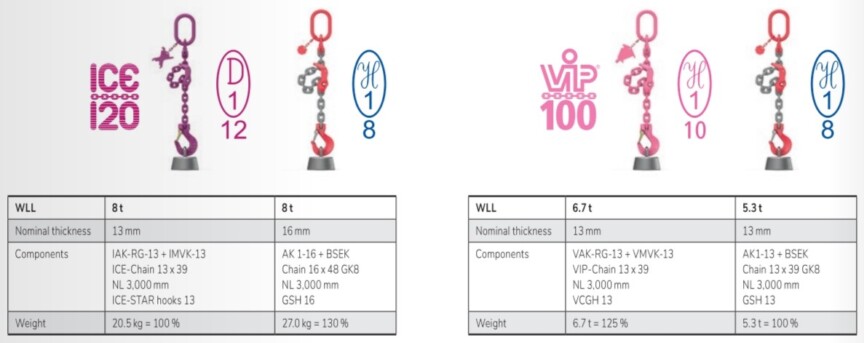

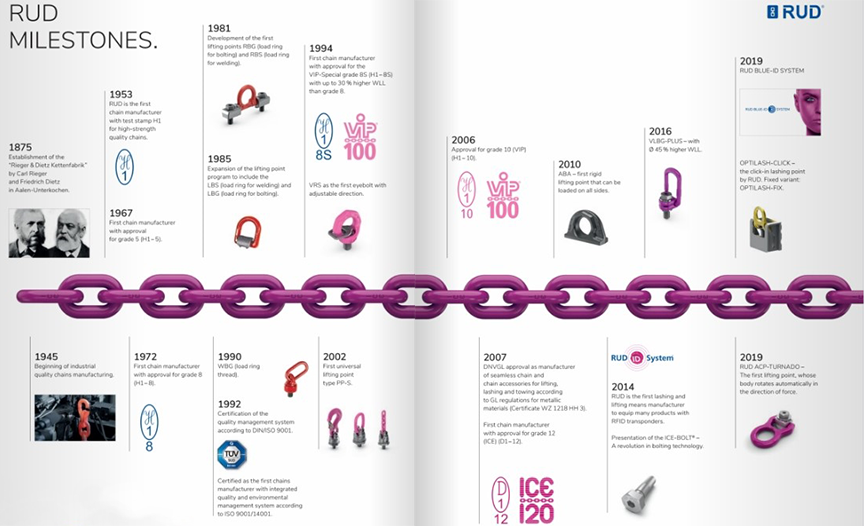

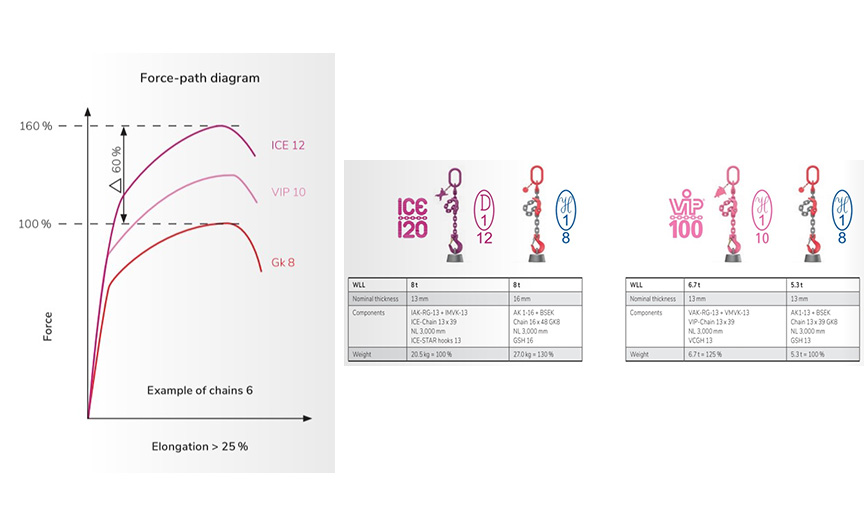

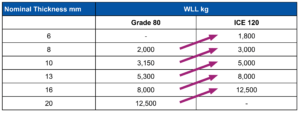

Several chain grades (Grade 80, 100, 120) exist, each with its own WLL (Working Load Limit). Selecting the appropriate grade is crucial for safety and efficiency.

Grade 80: This has been in existence since 1970. It is very popular in some parts of the world because it offers affordability. However, it has a lower breaking force and weight limitation.

Tip: RUD was the first chain manufacturer, approved for Grade 80 in 1972

Grade 100: It has been in existence for the last 30 years and is popularly used by many operators. It is a step up over Grade 80 and provides a balance between cost and performance.

Tip: RUD launched Grade 100 as VIP (Verwechslungsfrei in Pink) in 2006, and it is still a popular product used in many lifting applications. Click here for more details on the RUD VIP Grade 100.

Grade 120: Grade 120 is the latest and strongest grade, offering lighter weight and higher breaking force than Grade 80. Exclusive to a few manufacturers (including RUD).

Tip: Grade 120 offers a 30% reduction in weight than Grade 80 because it uses less material. It also possesses a 60% higher breaking force than a Grade 80 chain, and it is extremely robust, tough, and resilient to sharp and rough edges.

What this means is that an ICE Grade 120 Lifting or Lashing Chain - no matter the nominal thickness - can replace a Grade 80 chain of a next-higher nominal thickness.

Click here for more details on RUD ICE 120 Chains.

To be continued ...

Article copyright to RUD Australia. This information is accurate at the time of publication, and RUD Australia takes no responsibility for any errors, inadvertent or otherwise. Some pictures are for illustration only.

Mining in Chile is concentrated in the Norte Grande region spanning most of the Atacama Desert. The Atacama Desert lies 60 km southeast of Calama and is known as the driest desert in the world. The biggest challenge for mining companies is the lack of water, which is vital to the mining processes for concentrating and leaching. Most mining companies extract water from aquifers located high in the Andes Mountains, while some get it pumped from the coast.

The mine that requested a solution from RUD, extracted copper and molybdenum ore from depths of 1000 mts. This mine used a pump that transported water through 144 km of pipes from the coast to the mine site.

The pump to transport water was huge, and its size and weight over several tonnes posed several challenges during maintenance and repair work. The mining company could only use shackles rated at 40kg per shackle and the weight of the total number of shackles to raise the pump made it impossible with this option.

To solve the weight problem, RUD offered a solution of using adjustable ICE endless chains with a nominal thickness of 16 mm. ICE endless chains are used to lash an object directly without lashing or lifting points. The advantage of ICE endless chains is that it can be secured and opened without tools and the chain can be adjusted in its loop diameter. The ICE endless chain can be used with an ICE multi-shortening claw to form a closed chain.

A safe solution weighing only 11 kg per chain with the overall weight reduced by 70%.

For more details on how RUD can help with your lifting requirements, please call us on 07 3809 1300 or fill out an enquiry form here.

Sources:

The reliability and safety of our products are central to our business. Our quality commitment is reflected in our integrated QM / UM-System, which ensures all RUD employees comply with the high quality and environmental standards set by us.

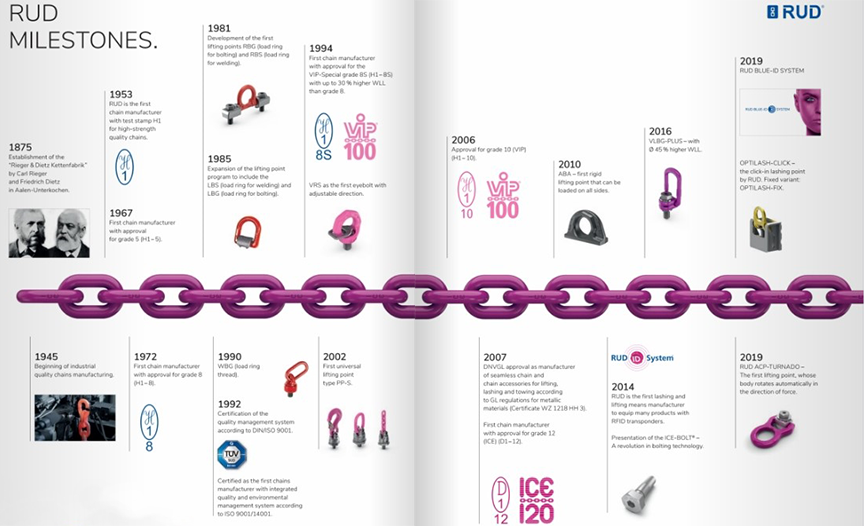

1953 marked a turning point in the history of the hoist industry when RUD became the first company to receive the H stamp for high-strength chains. The H stamp, which symbolises quality and safety, has revolutionised the world of lifting and lashing. RUD is the first manufacturer of new quality grades and carries the H1-stamp for Grade 60, Grade 80 and Grade 100. Seven decades later, RUD is still at the forefront of innovation.

Watch the new video, which looks at the stamp's origins and its role in quality and safety.

Established in 2008 by now co-Directors Ben Rose and Mitch Atkinson, Hulk Lifting seeks to supply high-quality engineered lifting solutions to whoever engages its services. Collaborating with German manufacturer and global supplier RUD Chains, Ben goes in-depth about the quality of RUD’s products and their impact on the lifting and rigging equipment industry.

In 2006, Ben Rose worked alongside his two colleagues Mitch Atkinson and Dan Bell in the gear locker for P&O Ports. The trio, doing their time in the stevedoring industry maintaining and inspecting lifting equipment, worked hard to keep all the products that came across their path up to a high standard while constantly seeking new ways to further develop the equipment on the Queensland port for cargo handling.

“Of course, it was at P&O Ports that we brainstormed and developed a self-equalising flat chain,” said Ben. “That was the inception of Hulk Lifting.”

Officially beginning in 2008 and now run by Ben and Mitch in the Brisbane suburb of Newmarket, the duo has expanded Hulk Lifting to distribute its lifting solutions across Australia. Designed predominantly for cargo handling in the stevedoring industry, Hulk Lifting products are capable of standing up in any environment: or, as Ben said, “to whoever wants to engage in our services and finds value in what we do”.

“We pride ourselves on creating innovative, engineered lifting solutions that are dependable, durable, and quality,” he said.

To supply the market with high-quality, bespoke lifting solutions, Ben is well aware that the foundation products need to come from high-quality manufacturing. As luck, fortune, serendipity, or - most likely - the importance of maintaining good relationships in the industry would have it, the team at Hulk Lifting already held a relationship with one such manufacturer: RUD Chains.

Globally renowned for its technical expertise in manufacturing and recently receiving a high appraisal from SureLift Crane Hire owner Mark ‘Chopper’ Read in the October issue of Cranes and Lifting as the “only products” he’ll use for lifting and lashing solutions, the German-based manufacturer’s product range features more than 700 lifting slings and lashing points. For Ben, the introduction to RUD’s products came in 2004 through Product Manager Stuart Nolan.

Since then, akin to SureLift’s experience, Hulk Lifting has consistently turned to RUD for any lifting and lashing solutions it needs, according to Ben.

“Knowing that we’re using RUD’s products provides us with a sense of comfort and reassurance,” he said.

“RUD really is ‘best-in-show’ for us: through the design, manufacturing and final build stages, everything is simply top-notch.”

Supplying its products across the country and, in some instances, globally, Ben is well aware of the importance of providing equipment that is structurally and physically sound, not least because of the safety element involved in the lifting, stevedoring and bulk-handling industries.

At the forefront of its products is the “globally renowned” flat chain sling that inspired the inception of Hulk Lifting; at the core of its flagship product is RUD’s Grade 120 chain.

RUD’s ICE Grade 120 chain carries 30 per cent less weight than the next nominal grade chain and a 60 per cent higher breaking force than a grade 80 chain, which offers a significant safety

advantage to anyone using its products. Designed and manufactured back at the company’s home base in Germany, the chain slings are then assembled and proof load-tested at its Australian facility in Brisbane, where the products go through a rigorous testing process to ensure the chains meet Australian Quality, Environmental and OH&S standards. On top of this, the global manufacturer also holds LEEA and NATA accreditation, ensuring it is part of the movement in the lifting and rigging industry that focuses on supplying the market with internationally accredited, quality products. For Ben, this gives the team at Hulk Lifting better peace of mind.

“We sleep easier at night with RUD’s engineering because, in our experience, it really is the safest,” he said. “We’ve worked with other products, and we’ve seen RUD’s chains consistently exceed others in their performance.”

Supplying the Australian lifting and rigging market with high-quality, durable, sustainable products comes at a price compared to its single, two-time, and maybe three-time use counterparts. The price, however, is one well worth paying, according to Ben, with the environmental, financial and operational benefits all paying large dividends to those who decide to invest.

“People who’ve worked with high-quality lifting and rigging equipment know the value of manufacturing such as RUDs,” he said. “Safety needs to be paramount in the lifting and rigging industry, which RUD’s chains provide to anyone using them.”

It’s not, however, just the ICE Grade 120 chains that put Ben and Mitch’s minds at ease. As a manufacturer, RUD also designs and creates a host of lifting beams, spreader beams and lifting and lashing points, with over 700 tested boltable and weldable lifting point variants featuring load ranges all the way up to 250 tonnes. Working with RUD to provide customised lifting solutions,

Ben points to the first production lug in the world, which was the 31.5-tonne capacity ABA, which the manufacturers shipped to Australia for Hulk Lifting to weld onto a lifting beam. As Ben was

quick to highlight, it’s that high level of commitment to anyone using RUD’s products and services that ensures the German manufacturer remains a high-quality partner, from product through to post-sale service.

“Whenever we get something in from RUD, there’s always an engineer coming afterwards to inspect the product and ensure that it’s performing exactly as it should,” he said. “RUD gives a top-end

service supplied by top-end people providing a top-end product to the Australian market.”

Have you checked our YouTube videos? Click here to visit the RUD YouTube channel.

Article copyright to Cranes & Lifting; this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors, inadvertent or otherwise. Some pictures are for illustration only.

For more details on how RUD can help with your lifting requirements, please call us on 07 3809 1300 or fill out an enquiry form here.

Sources:

Welcome aboard Australia’s leading material lifting and handling technology company.

Click the button to read about us, our products, news, blog posts and everything happening at RUD in Australia and around the world.

Indo Pacific International Maritime Exposition is Australia’s premier commercial maritime and naval defence exposition which will be held at the International Convention Centre (ICC) Sydney from Tue 7 - Thu 9 Nov 2023.

This year's expo is on track to be the largest iteration in 23 years, with key players from the maritime and naval defence communities.

RUD Australia is also a certified supplier to the Australian Defence Force. Some of the solutions we provide to the ADF are:

What does RUD offer?

We offer bespoke solutions for the challenging conditions in the maritime industry. Forged from Duplex Stainless Steel 1.4462, our products are suitable for corrosive applications, including the subsea ROV-Hook, which has been developed specially for rigging with underwater robots.

ROV Subsea Rigging Hook

RORO Weld-On Lashing Point

INOX-ABA Weld-On Lashing Point

INOX-STAR Bolt-On Lifting Point

TECDOS Drive Technology

TECDOS Drives can be used in linear, rotating, horizontal or vertical applications to:

Click here to visit the Indo Pacific International Maritime Exposition website.

Visit our booth in the Defence Jobs Qld Area from 7-9 Nov 2023 at the International Convention Centre to discuss our Maritime Lifting, Lashing and Drive Technology Solutions.

For more information on RUD Solutions for the Maritime Industry, click here to send us an enquiry.

This is taken from the article published in Cranes & Lifting Oct 2023 issue. Click here to read the original article.

Director of SureLift Crane Hire Mark ‘Chopper’ Read discusses his business and why the company consistently chooses RUD.

“They’re the best chains in the industry,” says Chopper. “All of RUD’s lifting and lashing equipment consistently performs on safety and durability measures; it’s because of the way we’ve seen RUD’s products perform that we don’t buy anything but RUD.”

Chopper himself holds an extensive career in the mining industry; working in and around shutdowns in the mining industry before starting Surelift; he’s seen it all; and that’s why when he labels RUD’s chains and slings as the “best”, he’s worked with, there’s an added element of legitimacy to his words.

SureLift Crane Hire was conceived in the mining town of Moranbah and began its operations with just one 20-tonne Franna crane. Since then, the Queensland-based company has expanded its fleet to include seven Franna P&C cranes, seven all-terrain cranes, a 280-tonne crawler crane and a variety of truck and trailer combinations.

“Initially, when I started the business, I reflected on my time in the shutdown industry and I saw the potential for more crane hire in the market,” he says. “I decided to try it out, and we’ve eventually grown into the business we are today.”

At the core of its operations, SureLift provides crane hire and transport services to businesses and individuals in Moranbah and its surrounding regions. Frequently employed by contractors working in the mining, construction, maintenance and industrial sectors, Surelift’s team of 48 full-time employees is well-versed in the crane and logistics industry, thanks to the company’s 17 years of experience.

“The biggest problem that we experienced when starting SureLift was just attracting the work,” says Chopper. “But we kept our heads down and worked hard, and eventually, things fell our way; today, we own over 16 cranes and operate across a range of projects.”

Part of working across a range of projects in the crane industry requires versatile, durable, safe lifting and rigging equipment.

“Although we’re general hire, the chains consistently stand up for us no matter what environment they’re placed in,” he says. “I initially came across RUD’s chains early on in my career and they have not disappointed me.”

The other blatant testimony to the working capacities of RUD's products is the industries in which they appear. According to Chopper, working with a range of clients in the defence, infrastructure, energy and engineering industries, RUD’s chains offer “capacity, versatility, and unique features” that other chains “just don’t have”.

RUD ICE Grade 120 range of lifting chains weigh 30% less than the next nominal grade chain but possess 60% higher breaking force than the Grade 80 chains. Also, when used with a balancer, a RUD ICE 16mm chain can lift up to 48 tonnes, the highest in its class.

“The balancer is a huge point of difference when compared to other options on the market,” says Chopper. “It allows us to lift at a higher capacity with the same level of safety.”

Aside from using its range of lifting chains and slings, Chopper is also highly complimentary of the lifting and lashing points that RUD supplies to SureLift. The German manufacturer offers more than 700 tested boltable and weldable lifting point variants with load ranges all the way up to 250 tonnes. Stringently tested and certified according to LEEA and NATA standards, Chopper says the versatility offered by the products is “incomparable”.

“Working in the shutdown industry, it’s imperative to get things right with dependable, durable products,” he says. “The weld on lift-points that we use are exactly that; having versatile gear that holds many applications at many ranges is essential.”

All these products collectively feature for Chopper are safety and excellent post-sale service and support. Talking about his relationship with RUD Chains and its after-sale service, Chopper says no stone is left unturned for RUD when it comes to ensuring the company supplies the right product according to Surelift’s needs.

“Their post-sale service is excellent; anything you need to talk to them about – whether it be the maintenance of the product, a new range that’s just come out, or different lifting solutions – they’re there,” he says. “Additionally, if we need any advice for setting up new slings or purchasing any new items, RUD are always on the other end of the phone, ready and willing to give us a helping hand – or, in this case, a sling.”

For the team at Surelift, since RUD’s products are manufactured, tested and maintained in accordance with Australian Quality, Environmental, and OH&S standards, including LEEA and NATA accreditations, this is more important than RUD’s high-quality post-sale service. Chopper believes RUD’s products tick all these boxes.

“At the start of the day, everyone’s got a right to go to work; at the end of the day, everyone’s got the right to go home safely,” says Chopper. “We feel that using RUD’s chains embodies that message of safety.”

RUD will be exhibiting at the Crane Industry Lifting Conference - CICA 2023 from 26-28 Oct 2023. Visit us in Booth #27/28 at the Perth Convention Centre to discuss our Lifting and Lashing Solutions for the crane industry.

Article copyright to Cranes & Lifting; this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors, inadvertent or otherwise.

Read More Articles on the Cranes & Lifting portal:

The CICA (Crane Industry Council of Australia) Conference is one of the biggest crane industry events in the southern hemisphere. CICA 2023 is being held at the Perth Convention & Exhibition Centre from Thursday 26 to Saturday 28 Oct 2023. RUD will be showcasing solutions for lifting, lashing and engineering requirements of the crane industry.

RUD Australia is a certified supplier to the crane and infrastructure industry, providing solutions such as:

Check our blogs on the Lifting Kits for Cranes, Lifting & Lashing Solutions for the Wind Energy Industry and lifting the largest and heaviest lattice cage for a bridge pier in Berlin.

Read why Mark Read from SureLift Crane Hire Services based at Moranbah says RUD chains are the best chains in the industry and consistently perform on safety and durability measures. And why you need to consider RUD Chains for your next lifting purchase.

Read the original article on Cranes & Lifting October 2023 issue here.

Visit us on Stands #27 and #28 from 26-28 Oct 2023 at the Perth Convention Centre to discuss our Lifting and Lashing Solutions for the crane industry.

For more information on RUD Solutions for the Crane Industry, click here to send us an enquiry.

Part 2 of the 2-part article. Click here to read Part 1.

Delivery Stage

RUD's lashing solutions are used to secure wind turbine components during transport. For example, the L-VLBG M36 lashing point is ideal for securing a nacelle.

Jens adds, "When it comes to reliable solutions for safe transport, you can depend on RUD technology. Poor quality load-securing products are the major contributors to accidents in the wind power industry. The cost of a new nacelle or postponing the commissioning of a turbine is costlier than investing in the right load-securing product”. ICE Grade 120 lashings reduce weight while keeping safety paramount. Products such as the ICE-CURT-GAKO ratchet tensioner prevent accidental release, which can happen from vibrations while driving.

Installation Stage

RUD offers custom lifting and handling solutions when installing heavy tower segments and rotor blades. Jens explains, “For lifting and erecting large and heavy tower segments, special attachment points are attached to the flanges of the segment. The RUD T-FRB (FLARIBO) flanged load ring was specially developed for such an application and features a patented thrust bearing washer incorporated into the lateral bearing for 90° loading."

Four FLARIBOs are mounted to the top of the segment and two FLARIBOs to the bottom to erect a tower segment. The segment is then lifted using two cranes and erected in the air. The sling chains move over the deflection rollers of the RUD VIP Chain Block (VCB). The VCB allows load balancing for the segment to be positioned vertically. The flange to flange can then be bolted together. When the four FLARIBOs are removed from the top of the tower segment, the deflection rollers of the VCB prevent the unloaded side of the chain from slipping through and falling.

After the tower is assembled from its individual segments, the next step is to mount the nacelle and hub assembly. "A lifting beam is used to lift the pre-assembled rotor blades for the hub assembly. The lifting beam has two generators and two hydraulic systems, which ensures safe assembly of the hub in the event of a partial failure of the system”.

Operation and Maintenance Stage

It is crucial to ensure personal safety mechanisms are in place while conducting maintenance operations. At such dizzying heights, there is no compromise on risk. The PSA-VRS STARPOINT has been specially developed to secure people by connection with the safety harness.

A RUD PSA-VRS STARPOINT can carry up to two persons, offering the advantage of safe securing of the victim and the rescuer in the event of an incident. The PSA can be rotated 360° and forms a compact securing unit with its special non-removable screw.

“The stainless-steel variant, PSA INOX-STAR, is designed for permanent outdoor use in challenging weather because of its corrosion resistance," says Christiansen.

Decommissioning Stage

Like installation and delivery, the same products can be used during dismantling and removal. For example, the flange load ring T-FRB (FLARIBO) and the VCB can be used to safely lift pipe segments. The L-VLBG M36 lashing load block, ICE-CURT-GAKO ratchet tensioner and ICE 120 lashing chains can be used during loading and transport.

Offshore plant?

Onshore wind turbines require products that are resistant to corrosion and challenging weather. The RUD ROV-HOOK, designed for subsea applications, is the first of its kind that can be operated with only one robot arm of a robot-operated vehicle, handling loads of up to 25 tonnes. Due to its integrated unique locking mechanism, accidental unhooking is impossible, which is a big plus point for safety.

RUD’s products offer safe and efficient applications in a wind turbine's life cycle from planning, production, transport and installation to maintenance and dismantling.

If you are facing challenges in the wind energy industry, RUD can keep your operations safe and efficient. Contact us today for more details on how we can help you.

RUD will be exhibiting at the Crane Industry Lifting Conference - CICA 2023 from 26-28 Oct 2023. Visit us in Booth #27/28 at the Perth Convention Centre to discuss our Lifting and Lashing Solutions for the crane industry.

Article copyright to RUD; this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors, inadvertent or otherwise.

Sources:

This is a 2 part article.

Wind power is currently the cheapest source of large-scale renewable energy, which involves generating electricity from the naturally occurring power of the wind. Wind turbines capture wind energy within the area swept by their blades. The spinning blades drive an electrical generator that produces electricity for export to the grid.

The Australian renewable energy industry accounted for 35.9% of Australia’s total electricity generation in 2022, up from 32.5% in 2021. This is more than double before the boom started in 2017 (16.9%). While there is still a significant way to go if Australia is to meet its ambitious 82% renewables by 2030, there has nevertheless been encouraging progress.

There are currently over 3,000 wind turbines in operation in Australia, generating enough electricity to power over 2 million homes. Some of the largest wind farms in Australia developed over the last few years include the MacIntyre, Coopers Gap and MacArthur.

While the wind energy industry creates jobs and economic opportunities in Australia, employing over 10,000 people and an additional 10,000 jobs by 2030, it faces a lot of operational challenges, such as:

RUD Solutions for the Wind Energy Industry

RUD is a world leader in lifting and lashing and offers a wide range of solutions for the wind energy industry to increase safety and efficiency in the design - manufacturing - logistics - installation and maintenance processes.

Reliability and Safety are Key in the Supply Chain

According to Jens Christiansen, RUD Slings Division Sales Manager for Germany, Austria, and Switzerland, "Logistics already starts with the design. The designer must plan how the component will be assembled, transported on the road or ship, and installed on-site in the design stage itself. As we know, wind energy includes components that are large and very heavy, which makes the job complex. As the leaders in lifting and lashing technology, we offer versatile solutions for all stages in a wind turbine life cycle”.

Where can RUD help?

RUD’s products and services are used throughout the life cycle of a wind turbine, from the design phase to decommissioning.

Idea and Design Stage

RUD lifting points are reputed for top quality, ergonomics and safety in lifting technology and load securing for more than 35 years. We offer more than 700 tested boltable and weldable lifting points in load ranges up to 250t, which meet maximum safety requirements. Our engineers can work with wind turbine manufacturers to design lifting and lashing solutions that meet the specific requirements of each project.

Production Stage

Whether lifting or moving small components or huge rotors, RUD has a solution for every task in the production process. Lifting, handling, or moving during production can be made more efficient using standard products. For example, the VLBG-PLUS Load Ring is suitable for lifting, rotating, and turning operations due to its large load-bearing capacity, excellent material properties (temperature/corrosion resistance) and ideal design. A VLBG-PLUS can be rotated 360° or swivelled 180° in the direction of the load. This makes it extremely easy to hook the sling into place, saving time and money.

RUD has also developed a Tool Mover with a capacity from 2.5 tons to up to 64 tons. RUD tool movers are widely used and accepted safety devices to guarantee the safe rotating and turning of turbines and critical components. Click to read how Enercon, a German wind turbine manufacturer is using RUD Tecdos Tool Mover to lift, move and turn large rotors of wind turbines.

RUD will be exhibiting at the Crane Industry Lifting Conference - CICA 2023 from 26-28 Oct 2023. Visit us in Booth #27/28 at the Perth Convention Centre to discuss our Lifting and Lashing Solutions for the crane industry.

To be continued ...

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Sources:

Welcome aboard Australia’s leading material lifting and handling technology company.

Click the button to read about us, our products, news, blog posts and everything happening at RUD in Australia and around the world.

RUD is a world-leading manufacturer reputed for top quality, ergonomics and safety in lifting technology and load securing for more than 35 years. We offer more than 700 tested boltable and weldable lifting points in load ranges up to 250t which meet maximum safety requirements in the crane industry. Our lifting points are also integrated into the crane during manufacture by leading crane manufacturers.

Hence, it makes sense to invest in RUD products, not just for safety but also to comply with site specifications. For example, our ICE Grade 120 chains are 30% lighter than the next nominal grade chain which means you carry less weight when lifting loads. Our VIP Maxi Construction Kit offers a WLL (Working Load Limit) of up to 126 tonnes when used with a combination of VIP chains in a double-strand configuration.

With RUD, you can be assured that your operations are safe on-site and for the crane operator.

What can RUD offer as a solution for your investment?

RUD Solutions for the Crane Industry

RUD has been providing lifting and lashing solutions for the crane industry in Australia and around the world. RUD products are trusted by some of the biggest companies in the mining, construction, and quarry industries.

RUD Germany provided lifting solutions for the Filstal Bridges along the Stuttgart 21 on the Wendlingen-Ulm route in Germany. The Fistal Bridges are the third-highest railway bridges in Germany made from pre-stressed concrete and are 485/472 mts in length and 85 metres in height at some points to the bottom of the Fils Valley.

In 2022, RUD Germany lifted the largest and heaviest lattice cage in Berlin. The lattice cage which was part of the infrastructure for a bridge pier in Berlin’s City Centre was 25 metres long and weighed around 56 tonnes. Read the full project here.

RUD Pre-Cast Concrete Hoops

RUD also offers Philipps Pre-Cast Concrete Hoops to lift bridge girders.

In 2022, RUD Australia supplied Philipps Pre-Cast Concrete Hoops to Universal Cranes to lift bridge girders on the Exit 41 M1 Pacific Highway Upgrade in Gold Coast. The 2 x span bridge consisted of 7 girders per span and each girder was 85t with 14 girders in total. Read more about the project here.

How can RUD ensure the safety of your crane, equipment, and people?

Safety is of critical importance in any industry. Accidents involving lifting and lashing points can have serious consequences, including injuries and fatalities. This is why it is very important to use high-quality lifting chains and lashing points that are designed to meet the highest safety standards.

RUD lifting chains and lashing points are the safest choices for you. All RUD products are made from high-quality materials and are designed to perform to the highest safety standards. RUD lifting and lashing points are also available across many sizes, WLL and LC, making them suitable for a wide range of applications.

Summary

We know your investment is important for your business growth. This is why we are happy to work with you to offer custom solutions for your business requirements. All our lifting and lashing products are specified to LEEA and NATA standards. If you are looking for a safe and reliable investment to boost your business profile, RUD is the perfect partner for you.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

For more details on how RUD can help with your crane requirements, please call us on 07 3809 1300 or fill out an enquiry form here.

Sources:

The RUD Mini-Lifter is made up of a master link with an integrated shortening option which is specially developed for the 4mm RUD ICE 120 lifting chain. The mini-lifter is designed and manufactured by RUD Germany and with an ICE 120 chain is ideal for lifting small loads up to 800 kg with a single-leg lift and up to 1.4 tonnes with a 2, 3 or 4-leg lift.

The mini-lifter is made from high-quality material and is designed to meet the highest safety standards. It is marked with the RUD-ID-TAG® (RFID chip) for easy identification.

The mini-lifter with the ICE chain is a versatile lifting solution that can be used in a variety of applications and is ideal for lifting small loads in tight or confined spaces. It is easy to use and maintain, and it is backed by RUD's commitment to quality.

Read more on the ICE mini-lifter here.

How will you benefit from a RUD ICE mini-lifter?

So, where can I use the RUD ICE mini-lifter?

Tips for Using Mini-lifters.

If you are looking for a versatile and reliable tool for lifting heavy objects in your workshop, a RUD ICE mini-lifter is a great option. Order your RUD ICE mini-lifter today and experience the RUD quality.

Call us on 07 3809 1300 or send us an enquiry here.

Introducing OPTILASH FIX and OPTILASH CLICK, a flexible system of lashing points. They come in an integrated retainer housing to add or remove lashing points and provide significant cost savings in the long term.

How can you benefit by using OPTILASH:

Available to order. Call us on 07 3809 1300 or visit our OPTILASH product pages FIX or CLICK.

Australia's biggest truck, trailer and automotive show, Brisbane Truck Show will be held at the Brisbane Convention Centre from 18-21 May 2023. RUD Australia and Endurequip Hoists will be on display on Stand #380 with the Australian-Made Portalift Hoists, A-Frame Trailer Adaptors, Vehicle Stands and the RUD Load-Securing Lashing Solutions.

The Brisbane Truck Show is recognised internationally amongst the world’s leading industry business events and organised by the Heavy Vehicle Industry Australia (HVIA) for over fifty years. The 2023 event promises the biggest line-up of trucks, trailers, components, equipment and technology in the Southern Hemisphere.

Endurequip Hoists is part of RUD Australia and is manufactured in Brisbane as a proud Australian-Made brand for over 35 years. It is the most trusted portable heavy vehicle hoist promoting Australian manufacturing through:

✅ Offering Superior Quality

✅ Supporting Local Businesses

✅ Supporting Local Job Creation

In addition, RUD will be showcasing load-securing solutions such as:

Brisbane Truck Show Information:

Exhibition opening hours:

For more information on RUD Load-Securing Solutions or Endurequip Hoists click here to send us an enquiry.

INOX-ABA is manufactured from Duplex Steel 1.4462 which is an ideal solution because it is resistant to corrosion from seawater, water vapour, chlorine, nitric acid and sulphuric acid.

It is also cost-effective due to its lower nickel content.

Suitable for:

Check out the features of INOX-ABA:

Available to order. Call us on 07 3809 1300 or visit our INOX-ABA product page here.

Continued from Part 1 on THE IMPORTANCE OF LOAD SECURING. Click here to read Part 1.

Tie-down Lashing

Tie-down lashing is the most common type of lashing for the transport of goods over the road. If the cargo is wide (if not wider than the truck tray), securing the load is only possible by vertical or slightly inclined tie-down lashing.

In the case of tie-down lashing, care must be taken to consider factors such as:

Note: Tie-down lashing only works if there is enough friction between the loading area and the load. For example, a steel load on a steel loading area does not offer enough friction which is why wooden supports or anti-slip mats should be used to increase friction.

Diagonal Lashing

For diagonal lashing, two angle plans (horizontal and vertical) should be considered and two angles defined. Diagonal lashing should be prioritised over tie-down lashing. This is because with diagonal lashing, the lashing equipment is not subject to pre-tensioning forces. The lashing equipment is only subjected to higher loads in the event of sudden braking, jerky start, or close cornering.

Are Lifting Points suitable for Lashing?

Lifting points are often installed for lashing purposes. However, lifting points are used primarily for lifting and therefore not marked with the permissible tensile force LC (Lashing Capacity - daN) but with their WLL (tonne). It is important to know that lashing points and lifting points are subject to different design factors. This is why you will find it easier to meet practical requirements with high-strength, tested, and field-proven RUD lashing points.

Weldable RUD lashing points are forged and available in blocks that can be easily welded. RUD lashing points with LC specification in daN can also be retrofitted to the vehicle carrier by certified welders. In addition to these weldable lashing points, RUD also offers an extensive range of boltable lashing points which can be used for load securing.

Tips for Skip Loaders - Optimum Load Securing with Angled Lashing

Load securing is always about the safety of people and the load. Also, having your load secure ensures that you do not run the risk of fines by the transport authorities. With RUD lashing products you be assured of safe transport of your cargo all the time.

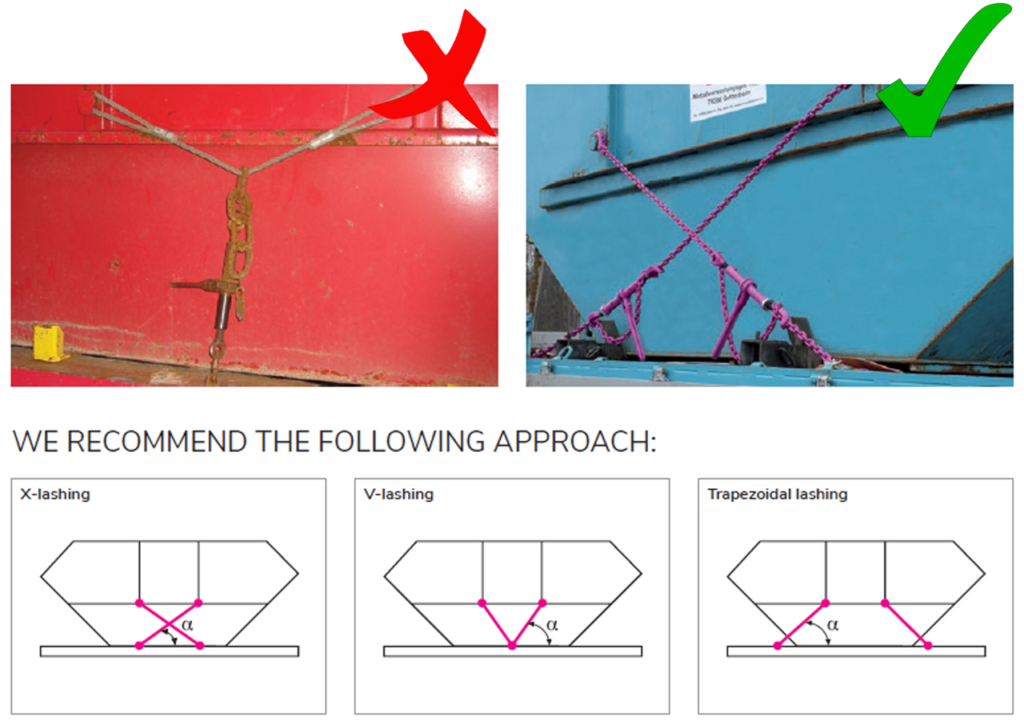

As shown in the pictures, tie-down lashing of trough containers is advisable in V, X, or trapezoidal angles with a fixed connection at the lashing point and the suspension pin. A Y lashing should be avoided because the load will not be adequately secured with this type of lashing.

Finally

If you are transporting heavy machines or cargo, it is important to plan load securing during the design phase components. This means, installing lashing points on both the load and the loading area.

Some of the points to note:

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

When transporting goods or equipment over the road, it is critical to ensure that the goods or equipment is securely fastened. Poor load securing could lead to accidents including human life, vehicle damage, and put road users at significant risk. In addition to the financial and human costs of accidents; there are other significant risks such as liability and negligence claims, criminal prosecution, legal action, higher insurance premiums, and damage to the company’s reputation.

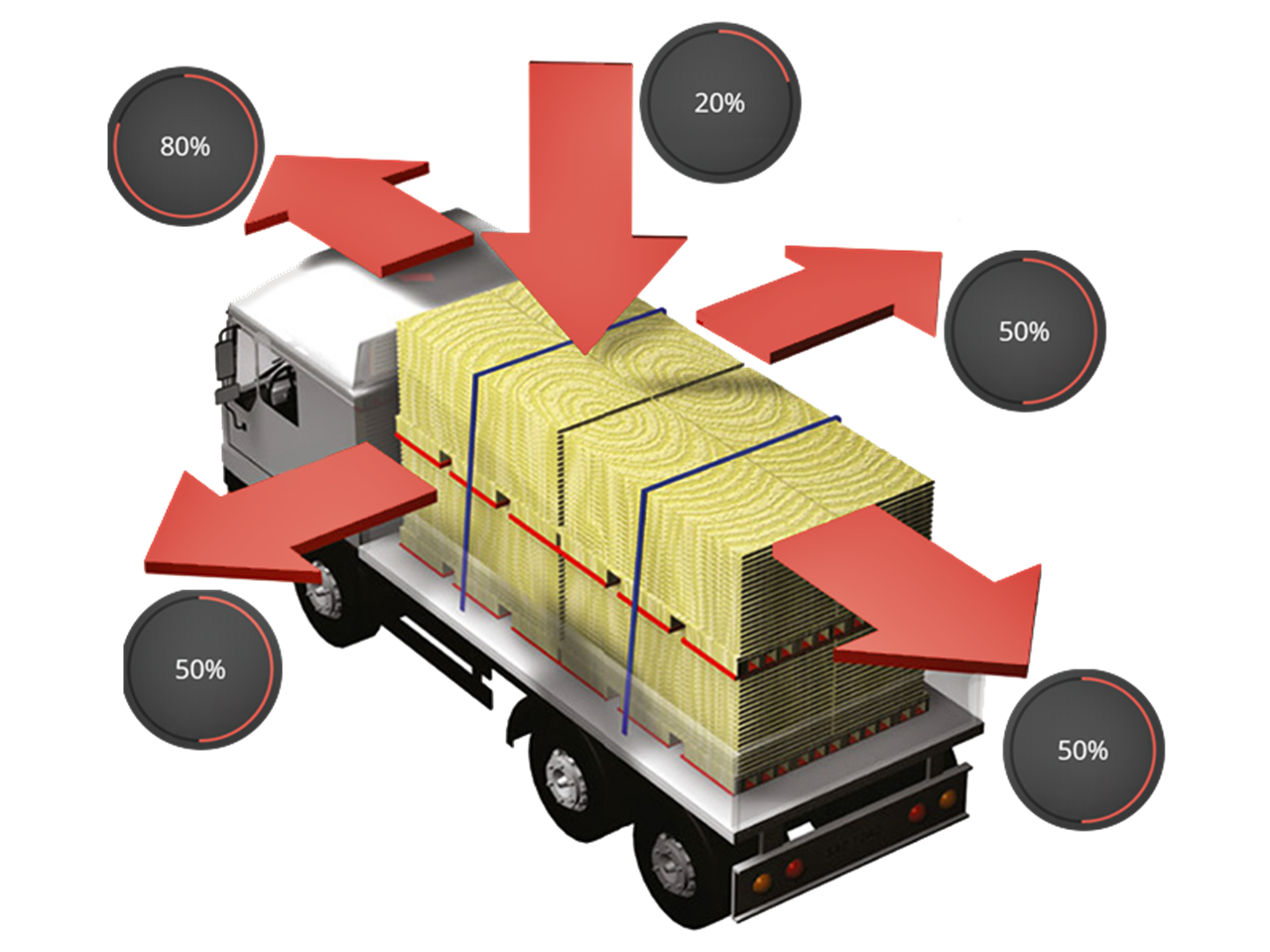

Load Securing

Cargo on a vehicle is subject to acceleration forces when the vehicle on which it is traveling accelerates, brakes, or changes direction. If the cargo on the vehicle is not securely fastened, this means the risk of the cargo moving forward, sliding backward, or tipping sideways is very high. Hence, when a vehicle brakes, the force of momentum will cause the unrestrained cargo to continue moving in its original (forward) direction and thereby cause significant risk of damage to the cargo itself, the vehicle, and possible personal injury to the driver or other road users.

Loaded vehicles are subject to 0.8g deceleration in forward movement, and 0.5g deceleration in both backward and lateral (sideways) directions*. For example, a cargo weighing 10 tonnes is subject to 8 tonnes of forward force and 5 tonnes either sideways or backward. Hence, the cargo must be secured to prevent damage, injury, and risks.

*Australian National Heavy Vehicle Register Load Restraint Guide 2018

Benefits of RUD Lashing Systems

RUD is the world leader and expert in lifting and lashing solutions. All RUD sling products are manufactured exclusively for lifting and load securing using cutting-edge technology. This is why our made-in-Germany innovative products set global standards for the lifting and lashing industry.

RUD offers a range of lashing points and lashing chains for optimal securing of cargo. Some of the popular RUD load-securing products for cargo transport are:

Load securing hints for heavy cargo

One of the solutions to secure heavy cargo is to use RUD lashing chains in double strands. (See picture below).

Endless-Chain Lashing

What happens if there are no lashing points on the cargo to secure the load directly? Using a shackle to connect the lashing chain to unsuitable lashing points is risky because it exposes the shackle to bending stresses. The best option in such cases is to use an Endless Chain that has the same Lashing Capacity (LC) as a lashing chain. And if the chain is “doubled-up”, sharp edges will not cause any problems.

An ICE-Endless-Chain can be used with an ICE-Multi-shortening claw (see last 2 pictures on right) to form a closed chain.

The advantages of such a configuration are:

RUD will be displaying in the Brisbane Truck Show from 18-21 May 2023 at the Brisbane Convention Centre. Visit us on Booth #380 (Plaza Level) to know more about our Lifting & Lashing Systems, Workshop Handling Solutions including Endurequip Portalift Hoists and Tyre Protection/Traction Chains.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

Continued from Part 1 on TOP 5 LIFTING & LASHING POINTS. Click here to read Part 1.

Top 5 lifting and lashing points from RUD

We have compiled a list of the top 5 lifting and lashing points below:

VLBG-PLUS

The RUD VLBG-PLUS Load Ring comes in standard and variable bolt lengths. VLBG-PLUS has a safety factor of 4:1 and comes fully tested and certified by DGUV. It is designed for use in extreme temperatures ranging from -40˚C up to 100˚C and maximum temperature of 350˚C.

The advantages of VLBG-PLUS:

VLBS LOAD RING

The VLBS LOAD RING comes with or without an internal holding spring. It is ideal for multi-directional loading with a safety factor of 4:1 and comes fully tested and approved by DGUV.

The advantages of VLBS LOAD RING:

VRS-F STARPOINT

The VRS-F STARPOINT rotates in the direction of the load. Available in several bolt lengths with corresponding washers and crack detected lock nuts in different threads.

The advantages of VRS-F STARPOINT:

ABA WELD-ON LUG

The ABA comes in both LIFTING POINT and LASHING POINT options which are ideal for construction projects that have constant rotary motion, strong vibrations and shocks. ABA has a safety factor of 4:1 and comes fully tested and approved by DGUV.

The advantages of ABA WELD-ON LUG:

ACP-TURNADO

The RUD ACP-TURNADO with a unique spring mechanism ensures higher safety by automatically rotating in the direction of force transmission. This eliminates the risk of a sudden release of the ring from this position in the direction of force and the resulting jerky dropping of the load - which endangers the load, load handling equipment and lifting system.

The advantages of ACP-TURNADO:

RUD has a long pedigree of manufacturing chains for over 140 years including 40 years in lifting technology and load securing. When it comes to lifting, securing, or lashing, the world looks to RUD which offers over 700 different lifting and lashing points for all requirements across mining, quarries, transport, and infrastructure.

All RUD lifting and load securing products are made in Germany. Many of the standards used in the lifting and load securing industry originated from RUD, such as the inspection stamp H1 for high strength chains in 1953, approval for Grade 8 (H1-8) in 1972 and approval for Grade 12 (D1-12) for round steel chains in 2007.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out a form here.

Sources:

Part 1 of a 2 part post.

RUD has a long pedigree of manufacturing chains for over 140 years including 40 years in lifting technology and load securing. When it comes to lifting, securing, or lashing, the world looks to RUD which offers over 700 different lifting and lashing points for all requirements across mining, quarries, transport, and infrastructure.

All RUD lifting and load securing products are made in Germany. Many of the standards used in the lifting and load securing industry originated from RUD, such as the inspection stamp H1 for high strength chains in 1953, approval for Grade 8 (H1-8) in 1972 and approval for Grade 12 (D1-12) for round steel chains in 2007.

What is a Lifting Point?

A lifting point is the part which connects the load with the lifting device (such as a crane) to lift, turn, rotate, and move cargo. Lifting points are attached with hooks, shackles, and other connecting elements.

Different types of lifting points

Lifting points come in boltable and weldable options and all RUD lifting points are designed for a dynamic load of 20,000 load cycles.

Boltable Lifting Points

Boltable lifting points are used generally to lift loads. Because they are bolted, they are flexible and can be used in applications which require installation and removal when required.

Examples of Boltable Lifting Points are VLBG-PLUS, ACP-TURNADO, VRS-F STARPOINT, etc.

The advantages of Boltable Lifting Points:

Boltable lifting points also come in rotating and swivel options where the lifting point swivels in the direction of the load to offer additional flexibility and safety.

Weldable Lifting Points

Weldable lifting points are used when there is a requirement for a permanent connection on the load. These are permanently welded to the load for rotating and turning.

Examples of Weldable Lifting Points are VLBS, ABA, etc.

The advantages of Weldable Lifting Points:

Weldable lifting points also come in rigid options where the direction cannot be changed and hence used in single leg lifts.

What do I need to consider when using lifting points?

Continued into Part 2 for the TOP 5 LIFTING & LASHING POINTS from RUD …

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out a form here.

Sources:

Continued from Part 1 on Tyre Protection Chains. Click here to read Part 1.

Lightweight Grade 120 Lifting Solutions

In mining, the size and weight of your equipment has a direct impact on yield and productivity. Our lifting and lashing solutions can increase efficiency and boost productivity.

RUD’s ICE Grade 120 chains are 30% lighter with 60% higher breaking force than Grade 80 chains. They are extremely robust, tough, resilient to sharp and rough edges and ideal for the harsh mining environment. The reduction in weight of more than 30% is a major safety advantage.

ICE Chains are assembled, and proof load tested in Brisbane. All RUD ICE sling assemblies are proof loaded at our 6000m2 facility in Brisbane - meaning you have peace of mind knowing that the sling is safe and able to perform the job it’s designed for - lifting safely.

Material Handling Solutions

RUD designs and produces conveyor systems for use in horizontal, vertical, and inclined applications. Our conveyor and drive systems are highly regarded for their high-performance & low-maintenance needs. RUD conveyor and drive systems offer numerous systems solutions for many applications whether it is for conveying, driving, or lifting. All conveyor and drive systems use round steel chains, forked link chains, screw drives or belts as traction mechanisms.

Our system range includes:

Engineered Solutions

RUD’s in-house engineers provide concept-to-completion solutions. Our accredited engineers help increase project productivity, efficiency, and safety by designing and delivering bespoke products and solutions. Our engineering team works with our manufacturing team in our 6000m2 Brisbane facility, designing and manufacturing customised engineering solutions for a range of industries.

All our products and solutions are rigorously tested to ensure they meet the high standards. Our quality control systems include compliance with ISO 9001, ISO 14001 and AS 45001.

Some of our testimonials:

“We see our long-term relationship with RUD more as a partnership than supplier and customer. RUD’s service and product support are excellent, and their team of industry specialists is always on hand to answer any of our questions” - Paul Denison, Bullivants Townsville.

“The team at Jilalan appreciate the quality service RUD provided in the design, fabrication, and commissioning of our platforms for our Wagon remediation project. RUD’s attention to detail and great communications skills ensured that our project was completed to the highest standard and exceeded our expectations. From the start of the procurement process, RUD committed to ensuring time frames could be met and delivered quality products as per agreement. We are grateful for this as no other company we contacted could make these commitments” - Gavin Witton Project Leader, CQCN North Wagon Operations, Aurizon.

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Some data is sourced from the below:

Australia is known worldwide as a mining country. Mining has been prevalent with the early settlers who heralded the gold rush in 1850 and were instrumental in bringing development during the early years. Mining is a major contributor to Australian economy, accounting for around 14.6% of the total Australian economy in 2021. For a complete snapshot of the Australian economy, download the Economy Composition Snapshot Chart.

There are over 350 operating mine sites across the country, one third of which are in WA and the balance two third are spread over Queensland and NSW. In Australia, WA accounts for 97% of iron ore while the east coast is majority coal production. Majority of coal mines are open cut with 1 in every 3 mines being underground.

RUD Group - Mining Solutions

For over 140 years, the RUD Group has been developing innovative chain systems and components for a wide range of applications in the mining sector around the world. In Australia, RUD offers a range of lifting and lashing points, VIP sling chain systems and tyre protection/traction chains for the mining industry.

RUD also offers a range of mining chains and connectors for use in armoured chain conveyors and beam stage loaders, covering all standard sizes, from 14x50mm through to 48x152mm. All sizes can be supplied in round steel link configuration while the flat link style is available only in the 38mm to 48mm size.

Tyre Protection Chains

The world reputed RUD tyre protection chains are a sought-after quality product for mining and quarrying trucks.

Tyre Protection Chains are required for 3 broad reasons:

RUD’s tyre protection chains:

At the Jundee Nickel Mine, extreme tyre wear and premature tyre failure had become an ongoing problem. Tyre issues were frequent but unpredictable. Replacement tyres were often difficult to source, leaving trucks and machinery out of service for long periods of time. RUD offered a solution, read the full case study of the Jundee Nickel Mine.

Continued into Part 2 to discuss lifting, material handling and engineered solutions...

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Some data is sourced from the below:

The CICA (Crane Industry Council of Australia) Conference is one of the biggest crane industry events in the southern hemisphere. CICA 2022 is being held at Adelaide Convention Centre on Friday 11 and Saturday 12 November. RUD will be showcasing solutions for lifting, lashing and engineering requirements of the crane industry.

RUD Australia is a certified supplier to the crane and infrastructure industry, providing solutions such as:

Some of the recent lifting solutions we have provided for infrastructure projects are the Exit 41 Pacific M1 Upgrade by Universal Cranes and lifting the largest and heaviest lattice cage for a bridge pier in Berlin.

Pictures from CICA 2019 and CICA 2022.

Visit RUD Australia on Stand 6.

For more information on RUD Solutions for the Crane Industry, click here to send us an enquiry.

The lifting and lashing industry in Australia use a range of equipment for lifting and lashing applications. There are a variety of lifting products that cater to the many requirements to lift, lash, move, and position loads.

Some of the different types of slings available in Australia are chain slings, wire rope slings, woven slings, synthetic slings, webbing slings and synthetic rope slings.

Choosing the right sling is dependent on factors such as:

RUD ICE (Innovative Chain Evolution) Grade 120 Chain uses high quality alloy steel that is quenched and tempered during the manufacturing process. A RUD ICE-chain is Grade 120 and can replace a Grade 80 chain of the next nominal chain size. This is due to the high strength of the patented material which makes it possible to achieve the nominal thickness even with a diameter of less than 16mm.

RUD ICE Grade 120 offers 30% reduction in weight compared to Grade 80 chain, using less material due to its light construction and easier handling. Grade 120 Chains possess a 60% stronger breaking force than Grade 80 chains, are extremely robust, tough, and resilient to sharp and rough edge. The reduction in weight of more than 30% is a major advantage for manual handling.

Chain slings can be configured in 1, 2, 3 or 4 legs and in a variety of lengths. Slings can be assembled with different attachments including master and connecting links, joiners, tensioners, clevis sling, grab shortening and self-locking hooks. Advantages of RUD ICE Chain Slings:

Summary

When choosing a lifting sling, importance should be given to a range of factors to not only ensure safety but also quality, reliability, and consistent performance. RUD chain slings are made in Germany and assembled/proof load tested in Australia - meaning you have peace of mind knowing that the sling is safe and able to perform the job it is designed for - lifting safely in accordance with Australian standards.

We provide lifting lashing solutions through an extensive Australia-wide distributor network servicing geographically dispersed and highly demanding industries.

Article copyright to RUD, some information may be accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Safely conducting lifts is an integral part of the RUD ethos.

Today on 9 July, RUD Chains Australia recognises Global Lifting Awareness Day (GLAD2020). This is a day to help spread the word about raising standards throughout the global lifting industry. RUD Chains Australia is a member of the event’s sponsor organisation, the Lifting Equipment Engineers Association (LEEA).

Since 1875, RUD Chains, has been leading the way in solving industry-specific materials handling issues. In Australia since 1984, RUD Australia is a trusted partner across many sectors including defence, infrastructure, power stations, mining and engineering industries.

Globally, RUD’s engineers are the experts in designing lifting-points which are designed to conduct lifts safely. Here at RUD Australia, our in-house engineers use that superior technology to design safe and efficient lifting solutions using RUD lifting points and RUD chains.

A lifting point refers to the connection between the load and the lifting or lashing means, or gear, used to lift or lashing down of the load. The RUD lifting point is used during the safe lifting of the load, as well as s secure point for lashing down of the load.

RUD’s lifting points are designed with quality, ergonomics, and safety in mind. The company holds 500 patents for its lifting point technology. Our lifting points feature more than 700 tested boltable and weldable lifting point variants capable of handling load ranges up to 250 t. They meet and exceed the most stringent requirements in all application areas when combined with our unique variety of ICE and VIP chain systems.

Our lifting products offer superior quality and safety in three distinct ways.

RUD’s boltable lifting points are designed to handle a dynamic load of 20,000 cycles and are tested at an overload of 50 per cent. All load-bearing parts are crack and load tested in compliance with International and Australian Standards and have WLL ranges from 100 kg to 250 t. RUD lifting points are available in all common thread dimensions (metric, inch, UNC, UNF etc.).

RUD weldable lifting points are designed for maximum load and are available for WLL ranging from 600 kg to 100 t, they provide safety in all loading directions. All the load-bearing parts have been crack-tested and load-tested in accordance with EN 1677. Our popular ABA and VLBS weld-on lifting points can be loaded in all directions and are virtually indestructible. They include patented wear markings inside and out.

Correct — and safe — load securing begins in the design phase. RUD engineers understand the importance of lashing points for the safe transport of heavy loads. Our lashing systems are made using the most advanced technology available to ensure the safe operation in all weather conditions and are designed to comply with International and Australian standards and are trusted by international and local Defence Forces.

Continued Innovation is the forefront of all RUD lifting points and two of RUD Chains Australia’s most popular lifting points offer superior lifting technology and added safety.

The VLBG PLUS evolved from the popular RUD VLBG load ring and includes an ICE-Bolt made from RUD’s patented fine-grain steel. The VLBG-PLUS offers up to 45 per cent higher working load limit than its predecessor for the same size thread.

RUD’s ACP-TURNADO is another new innovative and popular lifting point that is setting a new standard among centre-pull hoist rings. It comes equipped with a unique RUD spring mechanism and ICE-Bolt technology and provides up to 30 per cent higher working load limits than comparably sized hoist rings.

RUD Chains Australia is committed to continue building best practices in the Lifting Industry using a combination of our patented lifting points and engineered solutions. Our dedicated, in-house teamwork with our partners to provide innovative solutions with safety and efficiency as a key focus.

Reach out today to learn more about how our products can improve your lifting experience.

Hoist rings are special types of heavy-duty lifting rings used together with hoists for lifting and lowering loads. They have many applications wherever load work is involved, such as in the plastic processing, machine building, the tool and die industry, construction, and other industry sectors.

The problem with conventional centric lifting points, especially in 90-degree side load use, is that the lifting ring typically stays in the upright position during the lifting process. This often leads to what is known as the worst-case position, or dangerous transverse loading. When this happens, it can result in a number of high-risk scenarios:

These problems posed with using typical hoist rings are by no means minimal.

Simple. RUD Lifting and Lashing came up with an innovative spring mechanism that has dramatically improved the safety and efficiency provided by the RUD ACP-TURNADO

The benefits of using the RUD ACP-TURNADO in your business:

The mechanics of the new RUD ACP-TURNADO ensure that the anchor point always immediately turns in the load direction when raising the load. This prevents the possibility of a dangerous stop of the bracket occurring and the associated high-shearing forces.

This also rules out the highly-feared dropping of the load as a result of the sudden turning of the bracket. Moreover, through its optimised design and the special screw technology, the anchor point facilitates higher working load limits of up to 30 percent.

Simple Inspection and Maintenance

An RFID transponder is installed as standard to simplify the inspection of operating equipment, and ensure inspection and maintenance as well as documentation work is done quickly, efficiently, seamlessly and without fail. This, in turn, ensures the safety of RUD ACP-TURNADO use as well as the safety of your employees.

Ready to use RUD ACP-TURNADO?

If you’re thinking of adopting the RUD ACP-TURNADO for your business, we’re here ready to help. Contact a RUD Lifting and Lashing expert today or head to rud.com.au/lifting-reinvented

RUD Chains is one of the world’s biggest suppliers of load lashings and we supply everybody from transport companies and shipping yards to major rail freight companies. We work with the best, all around the world, and have established a reputation for delivering quality, strength and reliable solutions.

Here at RUD Chains in Brisbane, we have a team of qualified engineers on hand to help our customers with the important task of correctly calculating load lashings using RUD Chains.

We can also help design complex, fragile or extra-large loads that need a unique approach. Lashings and chains are our bread-and-butter and we go the extra mile to make sure our customers don’t have to.

Now, though, you can also refer to the free app that is available to download for both ioS and Android systems in your App Store. Simply enter some basic information and the app will do the hard work and come back with the basic calculations you need. Then along with referring to the Load Restraint Guide, you should have all your answers to be confident your load is secure.

If not, you can get in touch with us and gain the advice from a qualified mechanical engineer.

There’s the very real risk of an accident that can endanger lives, but it can also cause a serious financial fallout. The Chain of Responsibility legislation means that the whole supply chain, including the loaders and consignors, are equally responsible for every part of the delivery process.

So, don't let mistakes slip through the cracks. Download the RUD Lashing App right now and make sure your load is firmly fixed and safe to transport.

RUD Australia’s Managing Director, Mr Peter Nuttall, said becoming NATA accredited demonstrates RUD’s ongoing commitment to ensuring its engineered solutions, manufacturing process and proof loading facilities comply with global and Australian standards.“RUD Australia already takes great pride in offering an assurance in our products’ performance and longevity, with every lifting component undergoing demanding testing before being sent from our premises.” Mr Nuttall said.

“This new NATA accreditation, alongside our existing LEEA recognition and ISO accreditation, should provide added peace of mind to our customers. They can be confident that we will work and adhere to national and international guidelines to ensure our products perform at the highest level” he said.

The RUD mechanical testing facility offers a full suite solution for customers that entrust RUD to manage the entire product development process. From design and engineering, through to manufacturing, testing certification, dispatch and commissioning, RUD can partner with clients to solve complex design and engineering issues.

In addition to the mechanical testing of existing products, RUD is able to help customers remain competitive in a business environment where speed of supply is crucial. By providing lifting equipment that is ready for use without the need for customers to conduct their own testing, they can be more responsive knowing that all testing elements have been conducted and the products are ready for use.